Blog

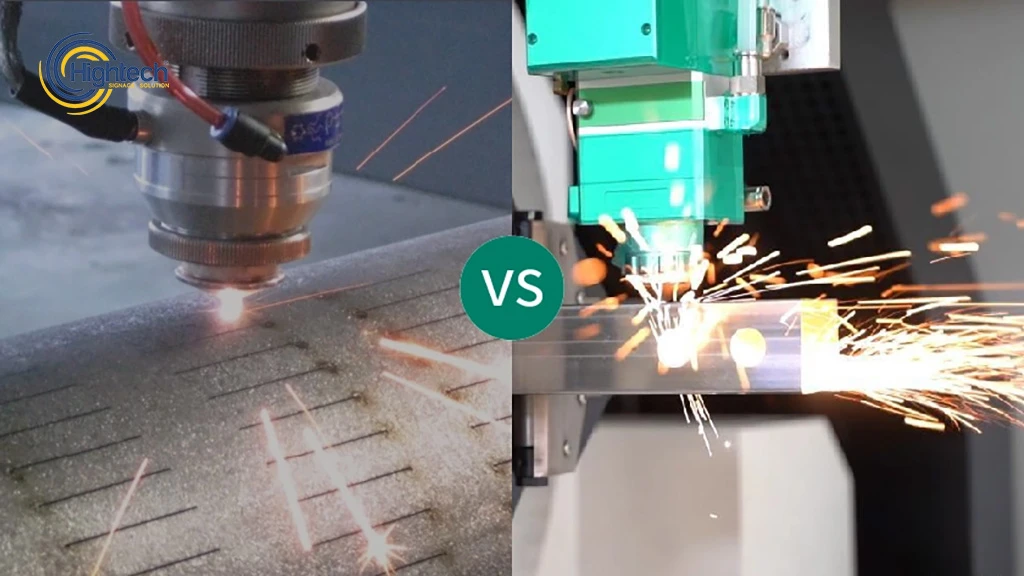

Fiber Lasers vs CO₂ Lasers for Metal: Which One is Best for Your Business?

Table of Contents

For modern metal fabrication, Fiber lasers are the industry standard for speed and efficiency, while CO₂ lasers remain relevant for specialised thick-plate cutting and non-metal versatility.

When evaluating Fiber Lasers vs CO₂ Lasers for Metal, the real decision comes down to ROI and operational costs, not just cutting capability.

Manufacturers focused on high-throughput metal processing prioritise fibre technology for its energy efficiency, long lifespan, and superior performance on reflective metals. In contrast, CO₂ lasers still hold value in workshops that require material flexibility or work extensively with thick mild steel.

Technical Snapshot: Wavelength & Physics Comparison

Feature | Fiber Laser | CO₂ Laser |

Wavelength | 1.06 µm | 10.6 µm |

Absorption Rate in Metal | High (3–10× better) | Low on bare metals |

Beam Delivery | Fiber optic cable | Mirrors and lenses |

Power Efficiency | ~30–50% | ~10% |

This fundamental difference in wavelength explains nearly every performance, safety, and cost distinction between fiber and CO₂ systems

Key Differences: Why Wavelength Changes Everything

The wavelength of a laser is not a theoretical specification—it directly determines cutting efficiency, material compatibility, safety, and long-term machine reliability. In real production environments, wavelength affects how much laser energy is absorbed by metal versus reflected back into the system.

This is why the comparison of Fiber Lasers vs CO₂ Lasers for Metal always starts with physics. Understanding wavelength behaviour explains why fibre lasers dominate modern metal fabrication, especially when working with thin sheets, reflective materials, and high-speed automated lines.

Fiber’s Shorter Wavelength: The Key to Metal Absorption

Fiber lasers use a 1.06 µm wavelength, which is absorbed far more efficiently by metals such as stainless steel, aluminium, and titanium. This allows more laser energy to convert directly into cutting power rather than being lost as reflected heat.

In practical terms, this means:

- Faster cutting speeds

- Lower power requirements

- Cleaner kerf quality on thin and medium-gauge metals

This is why, in most industrial comparisons of Fiber Lasers vs CO₂ Lasers for Metal, fibre systems dominate high-volume production environments.

CO₂’s Reflectivity Issue: The Risk of Optical Damage

CO₂ lasers operate at 10.6 µm, a wavelength that many metals—especially copper and brass—reflect rather than absorb. This reflectivity is a deal-breaker for CO₂ systems when processing bare reflective metals.

Reflected CO₂ laser beams can:

- Travel back into the optical path

- Damage mirrors and lenses

- Cause sudden system failure or downtime

For copper and brass, fibre lasers are not just faster—they are significantly safer and more reliable.

Performance Comparison: Speed, Thickness, and Precision

Performance differences between fiber and CO₂ lasers become most visible on the shop floor, where cutting speed, edge quality, and consistency directly affect production costs. The right laser is not simply the most powerful one, but the system that matches material thickness, daily workload, and quality expectations. In evaluating Fiber Lasers vs CO₂ Lasers for Metal, manufacturers must consider how each technology performs across thin sheets, thick plates, and precision applications such as marking or engraving.

Thin Metal Speed: The 1/4 Inch (6mm) Benchmark

For materials under 1/4 inch (6mm) thickness, fiber lasers are significantly faster than CO₂ lasers.

This benchmark is widely accepted across the industry and directly impacts throughput and profitability.

Fiber systems excel here because:

- Energy absorption is immediate

- No warm-up time is required

- Acceleration and pierce times are shorter

For businesses processing thin stainless steel, aluminium, or mild steel sheets, fibre is the clear productivity leader.

Thick Materials and Edge Quality: Where CO₂ Still Competes

CO₂ lasers still compete in cutting very thick mild steel, particularly above 10–12 mm.

In these cases, CO₂ systems can produce a smooth, sometimes “mirror-like” edge finish that certain industries value.

However, this advantage is narrowing rapidly as high-power fibre lasers continue to improve thick-plate performance.

Precision Marking and Engraving on Stainless Steel

For fine marking and engraving on stainless steel, fiber lasers provide:

- Higher resolution

- Greater consistency

- Minimal heat-affected zones

This precision makes fibre ideal for serialisation, QR codes, and industrial branding.

Financial Impact: Operating Costs and Maintenance

When comparing Fiber Lasers vs CO₂ Lasers for Metal, the real decision is often driven less by cutting capability and more by long-term operating economics. While CO₂ systems typically appear cheaper at the point of purchase, their ongoing energy consumption, maintenance requirements, and consumable costs significantly increase total cost of ownership. Fiber lasers, by contrast, are engineered for efficiency and longevity, making them a strategic investment for metal-focused production environments where uptime and predictable costs matter.

The 50% Efficiency Rule: Cutting Your Power Bills

Add Your Heading Text Here

Fiber lasers convert nearly 50% of electrical input into usable laser energy, whereas CO₂ lasers typically operate at around 10% efficiency. This difference alone can reduce electricity costs by more than half in high-duty cycles. In real-world production, this translates into thousands of dollars saved annually, especially for facilities running multiple shifts. Lower power consumption also means reduced heat generation, easing cooling demands and extending component lifespan.

100,000 Hours of Service: Why Fiber Source is a Long-term Asset

Modern fiber laser sources are rated for up to 100,000 operational hours, compared to CO₂ laser tubes that often require replacement after 8,000–20,000 hours. This eliminates frequent downtime, recalibration, and costly tube replacements. Over a 10-year production horizon, fiber lasers function as a stable capital asset rather than a consumable-heavy system, reinforcing why their higher upfront cost is offset by durability.

Operational Costs: $4/hr (Fiber) vs. $20/hr (CO₂)

On average, fiber laser systems operate at approximately $4 per hour, while CO₂ lasers can reach $20 per hour when factoring in electricity, gas consumption, optics maintenance, and downtime. This cost gap becomes decisive in high-volume environments. When evaluating fiber laser vs co2 laser cost, most manufacturers find that fiber systems achieve ROI within 12–18 months, particularly in metal-only production lines.

Material Versatility: Beyond Just Metal

Although both technologies are capable of cutting metal, their material versatility differs substantially. Choosing between a fiber laser or CO₂ laser often depends on whether a business prioritises metal specialisation or material diversity.

CO₂ as the Hybrid Choice (Wood, Acrylic, and Coated Metals)

CO₂ lasers excel in non-metal applications such as wood, acrylic, leather, and plastics. They also perform adequately on coated or anodized aluminum, where surface absorption is sufficient. For workshops that require a single machine for signage, decorative panels, and light metal work, CO₂ systems retain value due to their multi-material flexibility.

Fiber as the Metal Specialist (Aluminum, Titanium, and Brass)

Fiber lasers are purpose-built for metals, particularly aluminum, stainless steel, titanium, copper, and brass. Their shorter wavelength is absorbed efficiently even by reflective metals, making them the only practical choice for modern metal fabrication. For raw or polished metals, fiber technology is not just preferable—it is essential.

Decision Matrix: Which One Suits Your Business?

Choosing between Fiber Lasers vs CO₂ Lasers for Metal is ultimately a strategic business decision, not just a technical one. The right choice depends on your dominant materials, production volume, operating cost tolerance, and long-term growth plans. While both technologies are capable, they serve fundamentally different production models. This matrix simplifies the decision by aligning each laser type with real-world manufacturing priorities.

Choose Fiber Lasers If…

Fiber lasers are the optimal choice for businesses focused on high-efficiency metal processing, where speed, safety with reflective materials, and long-term cost control are critical.

- More than 70–90% of your production involves metal

- You regularly cut aluminum, stainless steel, copper, or brass

- High-speed cutting of thin sheets (≤6mm) is critical to throughput

- You want low operating costs, minimal maintenance, and long uptime

- ROI within 12–18 months is a key financial objective

Choose CO₂ Lasers If…

CO₂ lasers are better suited for workshops that prioritise material diversity and non-metal cutting over maximum metal-cutting efficiency.

- Your workshop processes wood, acrylic, plastics, and coated metals

- You occasionally cut metal but prioritise material flexibility

- Your focus is thick mild steel where edge smoothness is valued

- Higher operating costs are acceptable in exchange for versatility

- You operate a craft, signage, or mixed-material fabrication shop

Strategic Business Selection Guide

Business Factor | Fiber Laser | CO₂ Laser |

Primary Application | Metal-only fabrication | Mixed materials |

Thin Metal Productivity | Industry-leading | Limited |

Reflective Metal Capability | Fully supported | High risk |

Energy Efficiency | ~50% | ~10% |

Maintenance Downtime | Very low | Frequent |

Typical ROI Timeline | 12–18 months | Longer, variable |

Final Business Verdict

If your operation is predominantly metal-focused, fiber technology is the only financially logical and future-proof choice. CO₂ lasers remain viable for diversified workshops, but they are no longer competitive for high-volume metal fabrication. Contact us to receive a detailed machine catalogue and application guidance.

Frequently Asked Questions

1. Which laser is better for stainless steel?

Fiber lasers offer faster cutting, better absorption, and lower operating costs.

2. Can a Fiber laser cut wood or acrylic?

No, fiber lasers are optimised exclusively for metal materials.

3. Why is Fiber laser more expensive upfront but cheaper to run?

Higher efficiency, longer lifespan, and minimal maintenance reduce lifetime costs.

4. Which laser is safer for reflective metals like copper?

Fiber lasers are specifically designed to handle reflective metals safely.

5. Can a CO₂ laser cut copper?

No, copper reflectivity makes CO₂ cutting unsafe and impractical.

6. Which laser lasts longer?

Fiber lasers significantly outlast CO₂ laser tubes.

7. Is Fiber faster than CO₂?

Yes, especially on metals thinner than 1/4 inch (6mm)