Blog

Fiber Laser Welder and Cleaner Applications | 2025

Table of Contents

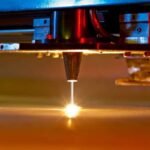

Metal fabrication demands precision, speed, and reliability. Traditional welding methods such as MIG and TIG have served industries for decades, but they often cause large heat-affected zones, material distortion, and require extensive pre- and post-weld cleaning. These drawbacks reduce productivity and increase costs. The rise of the fiber laser welder and laser cleaner has changed the game.

With faster operation, minimal distortion, and eco-friendly cleaning, they deliver consistent results across applications like stainless steel welding, aluminum joining, and sheet metal fabrication.

What’s Wrong with Traditional Welding?

Traditional welding methods like MIG and TIG are reliable but come with several limitations that affect quality, efficiency, and cost.

- Heat-Affected Zone (HAZ): Creates wider thermal impact, leading to weaker joints and visible marks.

- Material Distortion: High heat often warps thin metals such as aluminum and stainless steel.

- Speed & Productivity: Slower compared to fiber laser welding, especially for complex joints.

- Pre- and Post-Weld Cleaning: Requires chemical or mechanical cleaning to remove rust, oil, and oxidation.

- Consistency Issues: Results depend heavily on operator skill, making repeatability difficult.

Why Fiber Laser Welder is a Game-Changer

A fiber laser welder has transformed modern metal fabrication by solving the common drawbacks of MIG and TIG welding. With faster speed, minimal heat-affected zones, and reduced material distortion, it delivers higher consistency and repeatability. Whether in sheet metal fabrication, aluminum welding, or stainless steel welding, this technology provides unmatched precision while saving time and costs.

Welding Like a Pro Without the Experience

One of the biggest advantages of a fiber laser welder is its ease of use. Unlike traditional welding that requires years of practice, this machine allows even beginners to achieve professional-quality welds.

The high accuracy and portability of fiber laser welding machines ensure smooth seams without extensive post-weld cleaning or grinding. This not only improves surface finish but also supports faster productivity.

Perfect for Complex Joints by Fiber Laser Welder

Fiber laser welders excel in handling intricate designs and hard-to-reach joints that are often challenging with MIG or TIG. Their pinpoint laser beam reduces material distortion, even on delicate metals like aluminum and stainless steel.

By minimizing contaminants such as oxidation, oil, and rust during the welding process, they create stronger and cleaner joints. This makes them an essential tool in industries where precision and durability matter most.

Laser Welding vs. Traditional Welding: A Side-by-Side Comparison

Both laser welding and traditional welding (MIG, TIG) are widely used in metalworking, but they differ greatly in efficiency, quality, and overall results. Traditional welding has been the industry standard for decades, yet it often struggles with precision, speed, and repeatability.

In contrast, fiber laser welding cutting machines deliver cleaner welds, less distortion, and faster performance, making them ideal for modern manufacturing.

Feature | Traditional Welding (MIG/TIG) | Fiber Laser Welding |

Heat-Affected Zone | Large, risk of weak joints | Minimal, stronger welds |

Material Distortion | Common in thin metals | Greatly reduced |

Speed / Productivity | Moderate, slower for complex joints | High-speed, efficient |

Cleaning Needs | Requires pre- and post-weld cleaning | Minimal cleaning required |

Skill Level | Operator-dependent, requires training | Easy to use, consistent results |

Material Compatibility | Limited to certain metals | Works on aluminum, stainless steel, brass, and more |

Surface Finish | Often requires grinding or polishing | Smooth, high-quality finish |

Eco-Friendliness | May use chemicals for cleaning | Eco-friendly, no chemicals |

Applications of Fiber Laser Welder

The fiber laser welder has quickly become a preferred tool in industries that demand precision, speed, and reliability. Its ability to minimize the heat-affected zone, prevent material distortion, and ensure consistent quality makes it suitable for a wide range of applications.

Sheet Metal Fabrication

Fiber laser welding is widely used in sheet metal fabrication because it offers smooth seams and fast production. Industries that manufacture enclosures, cabinets, or structural parts benefit from its high accuracy and reduced post-processing needs.

Aluminum and Stainless Steel Welding

Aluminum and stainless steel are notoriously challenging to weld with traditional methods due to their heat sensitivity. A fiber laser welder handles these metals efficiently, avoiding distortion and delivering a strong, clean weld. This makes it essential for industries like automotive, aerospace, and food equipment manufacturing.

Fiber Laser Cleaners: The Unsung Hero of Metalwork

While welding receives much attention, laser cleaners play a critical role in ensuring high-quality results. Proper cleaning of metal surfaces before and after welding improves weld strength, prevents contamination, and enhances the final surface finish.

Pre-Weld Cleaning

Before welding, removing contaminants like oxidation, oil, and rust is essential. Fiber laser cleaners prepare the metal surface without altering its structure or generating excessive heat, ensuring consistent and strong welds. Pre-weld cleaning reduces defects and minimizes post-weld touch-ups, improving overall efficiency.

Post-Weld Cleaning

After welding, residues and oxidation can affect appearance and durability. Fiber laser cleaning removes these impurities, leaving a smooth, rust-free finish. This process is faster and more precise than traditional mechanical or chemical cleaning, making it a vital step for both aluminum welding and stainless steel welding projects.

Laser Cleaning for Stainless Steel: A Rust-Free Finish

Laser cleaning provides a precise and chemical-free method to prepare stainless steel surfaces, ensuring a smooth, rust-free finish. Compared to traditional cleaning, it reduces labor, prevents material damage, and enhances weld quality.

Replacing Traditional Cleaning Methods

Fiber laser cleaners eliminate the need for abrasive tools, chemicals, or manual scrubbing. By removing oxidation, oil, and other contaminants efficiently, they improve post-weld cleaning results, save time, and maintain surface integrity, making them ideal for modern fabrication workflows.

CO₂ Laser Cutting Explained | How It Works, Benefits, and Best Uses

The Power of Fiber Laser Welder Technology in Numbers

Fiber laser welding and cleaning offer measurable advantages over traditional methods, making them indispensable in modern metal fabrication.

Key benefits include:

- Speed & Productivity: Fiber laser welders complete complex joints faster than MIG or TIG methods.

- Precision: Minimal heat-affected zone ensures cleaner welds and less post-processing.

- Eco-Friendly Cleaning: Laser cleaners remove contaminants without chemicals, protecting both metal and the environment.

- Versatility: Works on aluminum welding, stainless steel, and other sheet metals.

- Consistency / repeatability: Produces uniform welds regardless of operator experience.

Cost Savings: Reduced labor, less rework, and lower material waste.

Conclusion: The Future of Welding and Cleaning is Here

Fiber laser welders and laser cleaners represent the next generation of metal fabrication. They combine speed, precision, eco-friendly operation, and ease of use, making them essential for modern sheet metal, aluminum, and stainless steel applications.

7 thoughts on “Fiber Laser Welder and Cleaner Applications | 2025”

Sir,

Please, send me catalog and prices.

Thank you.

Hi,Thank you for reaching out. We’ll be happy to send it over to you via Email

0548043624

Hi,Thank you for reaching out. We’ll be happy to send it over to you via Email

How much is your laser welding machine please?

Hi,We will send you a price list via email.

Hi,Thank you for reaching out. We’ll be happy to send it over to you via Email