Blog

Ultimate Guide | Channel Letter Bending Machines 2025

Table of Contents

Channel letter signs are among the most common forms of modern signage, valued for their clarity and professional appearance. At the heart of their production is the channel letter bending machine, a tool designed to shape metal or acrylic strips into precise letter forms.

By automating and refining the bending process, these machines help sign makers achieve consistent quality, reduce manual labor, and deliver durable results that meet the growing demand for attractive and reliable signage.

What is a Channel Letter Bending Machine?

A channel letter bending machine is a key tool in sign-making equipment, designed to shape metal or acrylic strips into accurate curves and angles for 3D channel letters.

It simplifies the bending process, ensuring precise letter returns and consistent quality while reducing manual labor. Modern machines, including CNC channel letter benders, follow digital design files for fast, reliable, and repeatable results.

Definition and Basic Functions

A channel letter bending machine cuts, bends, and sometimes flanges metal or acrylic strips according to design specifications.

It produces smooth, precise shapes for illuminated or non-illuminated signage. CNC models integrate with letter-bending software to improve accuracy and minimize material waste.

Types of Channel Letter Bending Machines

Different machines serve different needs:

- Manual Channel Letter Benders – Hand-operated, cost-effective for small projects.

- Automatic Channel Letter Benders – Motorized for faster bending with reduced labor.

- CNC Channel Letter Benders – Computer-controlled for high precision and repeatable shapes.

- Material-Specific Machines – Optimized for aluminum, stainless steel, or acrylic bending.

Benefits of Using a Channel Letter Bender

Using a channel letter bending machine transforms the way sign shops operate. Instead of spending hours manually shaping letters, these machines streamline the process, save labor costs, and guarantee consistency in every project. From small custom jobs to large-scale commercial signage, the advantages are clear.

Speed and Accuracy

One of the biggest benefits is production speed. A CNC channel letter bender can shape materials in minutes, with precise angles and curves that match the design file.

This reduces human error, shortens turnaround times, and helps shops take on more projects without sacrificing quality.

Cost-Effectiveness for Sign Makers

Although the initial channel letter bender price may seem high, the return on investment is significant. By lowering labor costs, reducing material waste, and boosting efficiency, the machine quickly pays for itself. For sign makers competing in a fast-paced market, automation ensures long-term savings and stability.

Improved Letter Quality

Manual bending often leads to inconsistencies, visible seams, or uneven edges. Automatic and CNC channel letter bending machines eliminate these issues by producing smooth, uniform bends every time. The result is higher-quality signs with clean finishes—essential for clients who demand professional and durable branding solutions.

Types of Channel Letter Bending Machines

Not all channel letter benders are created equal. The right choice depends on your production volume, materials, and budget.

Below are the most common categories sign makers consider when choosing signage fabrication tools.

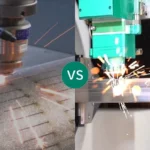

Manual vs. Automatic Channel Letter Benders

Manual benders are the entry-level option, operated by hand. They are inexpensive and practical for small shops or occasional projects, but require skill and patience. In contrast, automatic channel letter bending machines handle most of the work with motorized systems. They save time, reduce errors, and deliver consistent results—making them ideal for businesses with regular or high-volume sign orders.

CNC Channel Letter Bending Machines

A CNC channel letter bender represents the most advanced technology in this field. These machines are computer-controlled, reading design files directly from sign-making software. They deliver unmatched precision, allowing shops to produce complex letter shapes and curves with minimal waste. CNC systems are particularly valuable for large operations where accuracy and speed are critical to meeting customer demands.

Aluminum vs. Stainless Steel Letter Bending

The type of machine you need also depends on the material. Some machines are designed specifically for aluminum sheet bending, which is lightweight and easy to form. Others are built for stainless steel letter bending, which requires stronger tooling due to its higher strength and spring-back effect. Choosing a machine with the right material compatibility ensures clean bends without damaging the strip surface.

the global leader in channel letter bending machines and equipment

Hightech Industry Group

Key Features to Consider Before Buying

Before investing in a bending machine, it’s important to evaluate features that affect performance, material compatibility, and overall efficiency. Selecting a machine with the right capabilities ensures precise bends, faster production, and long-term reliability.

- Material Compatibility – Ability to bend aluminum, stainless steel, acrylic, or other metals without damage.

- Software and Control Systems – Integration with design files and intuitive interfaces for CNC or automatic models.

- Cutting, Slotting, and Flanging Options – Built-in tools to create precise slots, flanges, and cuts during the bending process.

- Speed and Automation Levels – Manual, automatic, or CNC control depending on production needs.

- Durability and Build Quality – Robust construction for consistent performance in professional sign shops.

Best Channel Letter Bending Machine Brands in 2025

Choosing the right machine often comes down to finding a reliable brand that balances quality, performance, and cost. In 2025, several manufacturers stand out for their innovation in signage fabrication tools and their ability to meet the demands of modern sign shops.

Top Manufacturers and Suppliers

Leading suppliers specialize in CNC channel letter benders and automatic channel letter bending machines that integrate advanced software with durable hardware. These companies are known for precision engineering, responsive customer support, and global distribution networks. The best channel letter machine brands offer training and after-sales services, which are essential for shops upgrading from manual systems.

Price Range and Value for Money

The channel letter bending machine cost varies widely depending on size, automation level, and material compatibility. Entry-level manual units are the most affordable, while fully automated CNC systems come with higher price tags. However, when considering the long-term savings from faster production, reduced errors, and improved quality, investing in a reputable brand often provides the best value for money.

Maintenance and Troubleshooting Guide

Proper maintenance ensures that a channel letter bending machine remains reliable and continues to produce high-quality results over time. Regular care helps prevent breakdowns, reduces repair costs, and extends the life of the machine, which is particularly important for high-volume sign shops.

Common Issues and Fixes

Even the best machines may experience occasional problems. Common issues include inconsistent bends, misaligned tools, or software glitches. Regular calibration, cleaning, and checking of mechanical components can prevent most of these problems. For CNC machines, ensuring that software updates are applied and files are correctly loaded also minimizes errors during production.

Routine Care to Extend Machine Life

Daily maintenance should include cleaning debris from the bending area, lubricating moving parts, and inspecting dies and rollers for wear. Periodically, a more thorough inspection of the machine’s motors, sensors, and control systems is recommended.

Choosing the Right Channel Letter Bender

Selecting the right channel letter bending machine is a critical decision for any sign-making business. Consider factors such as production volume, material compatibility, automation level, and the features you need, like cutting, slotting, or flanging. Manual machines suit small shops with occasional projects, while automatic and CNC channel letter benders provide speed, precision, and consistency for larger operations. Investing in a reliable brand ensures durable performance, reduces errors, and helps create professional-quality signs that meet client expectations efficiently.