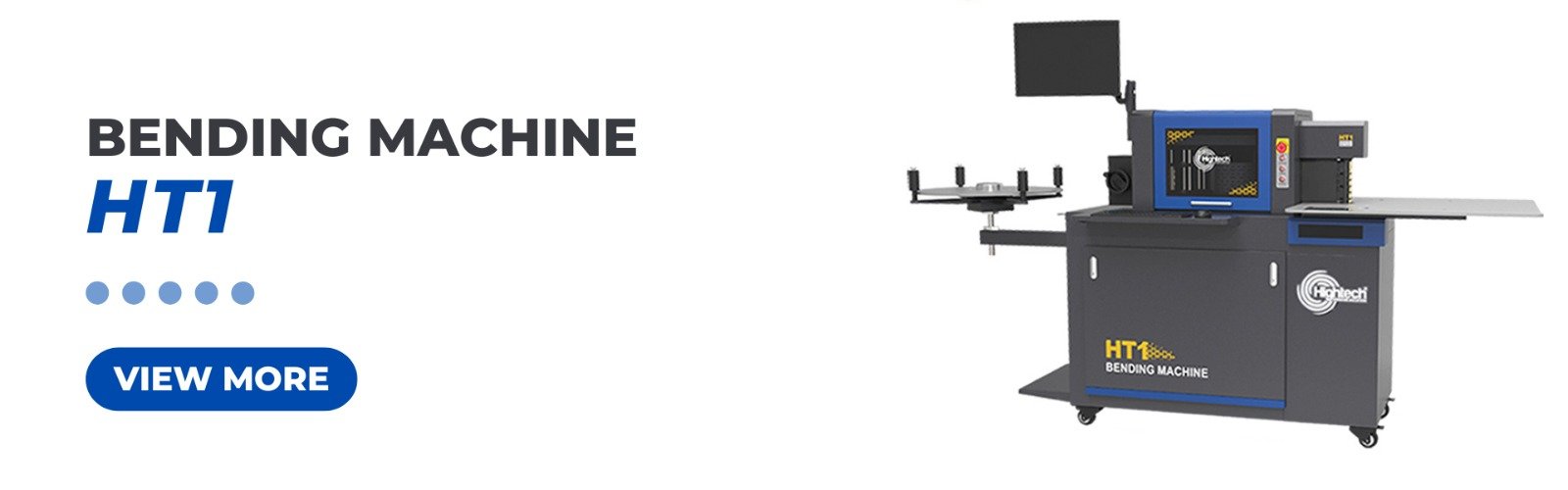

HT1 Channel letter bending machine

Categories: Channel Letter Bending Machines, Machinery

- ht1 channel letter bender

- Automatic Calibration

- Cutting Depth Adjustment by software

- Suitable for all types of aluminum strips and profile

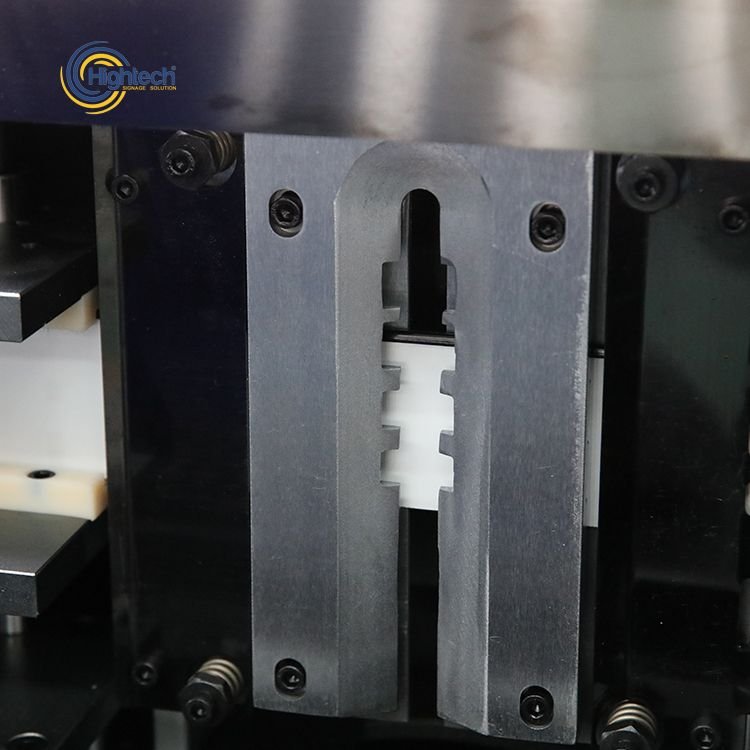

- Ability to cut and create a cutting line at different angles

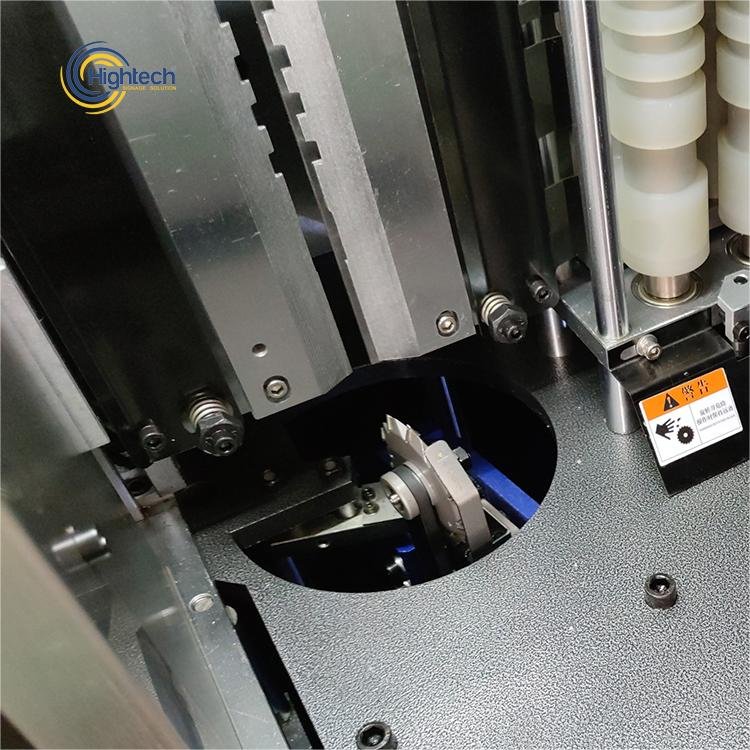

- From the front and back with the 360-degree milling cutter

Contains items:Complete machine + all accessories (computer/air compressor/spare parts) + tool box + training service

Product Gallery

Technical Parameters

| Cutting Method |

Milling cutter |

|---|---|

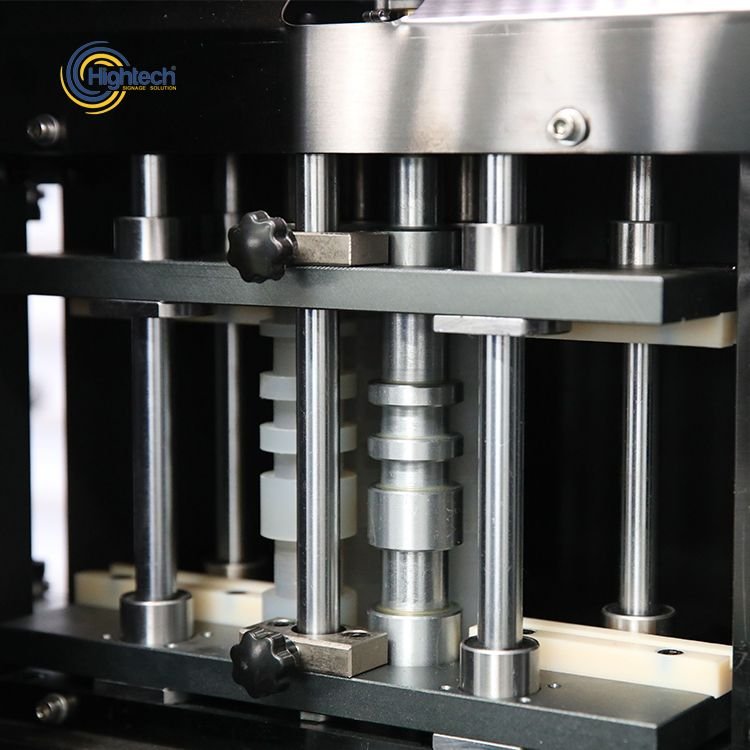

| Bending Method |

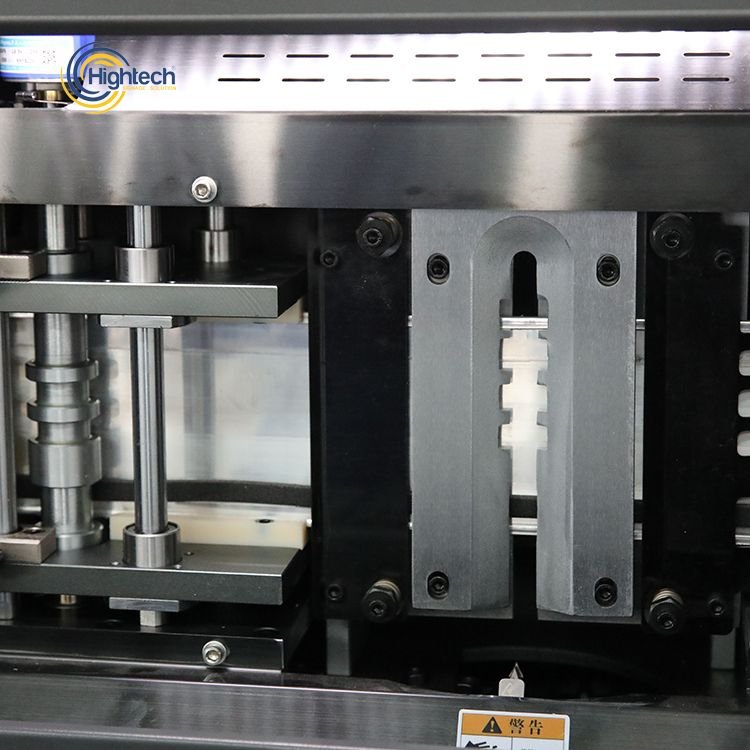

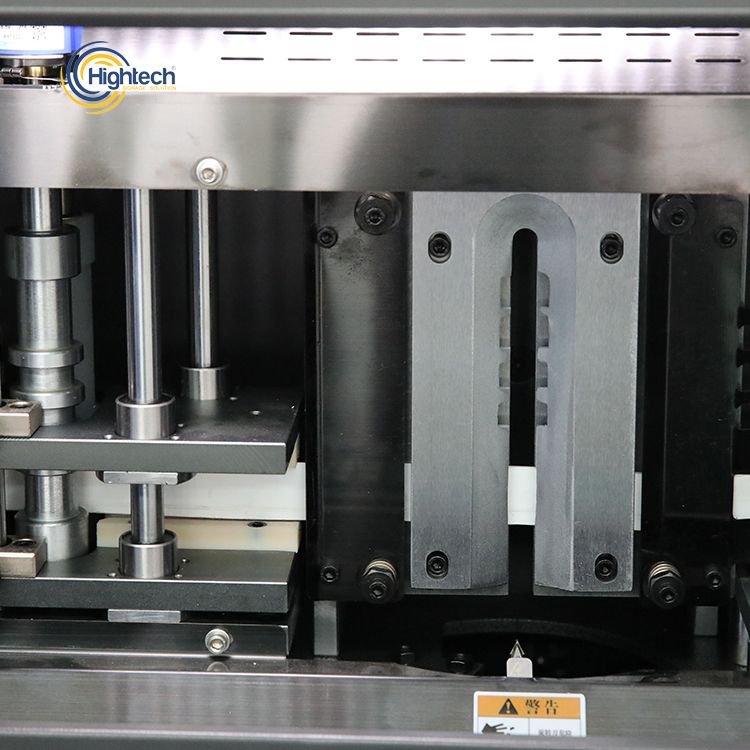

Double rod linkage bending method |

| Feeding Method |

Rolling feeding device |

| Minimum bending angle |

R15mm |

| Cutting depth calibration |

Automatic by software |

| Applicable Material |

Aluminum Extrusion profile ,Channelume ,Flat Aluminum ,Single Edge |

| Height of Material |

20-130mm |

| Material Thickness |

0.3 ~1.2 mm |

| Size Accuracy |

±0.1mm Input |

| Input File Format |

AI ,DXF ,PLT |

| Power |

Single Phase ,AC220V±10% ,1KW ,55Hz |

| Air Source |

0.6 m3/min |

Introducing HT1 Channel Letter Bending Machine

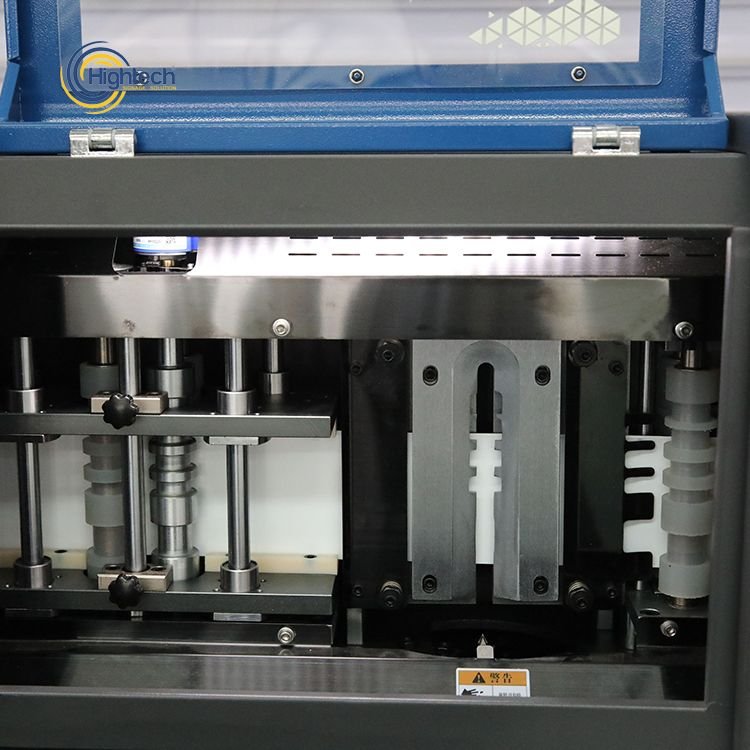

The HT1-N is a high-precision, fully automated bending solution built for next-generation signage production. Combining intelligent control, stable mechanics, and seamless workflow integration, it delivers exceptional accuracy and consistency with every curve and cut.- Smart automation system ensures precise calibration, reduced setup time, and effortless operation.

- Dual-milling and feeding design provides smooth, burr-free bending on aluminium and Channelume materials.

- High-strength alloy tools guarantee durability and long service life under continuous operation.

- Supports multiple input formats (DXF, AI, PLT) for fast design-to-production transitions.

- Compact industrial build with optimized maintenance and reliability for demanding production environments.

Key Features

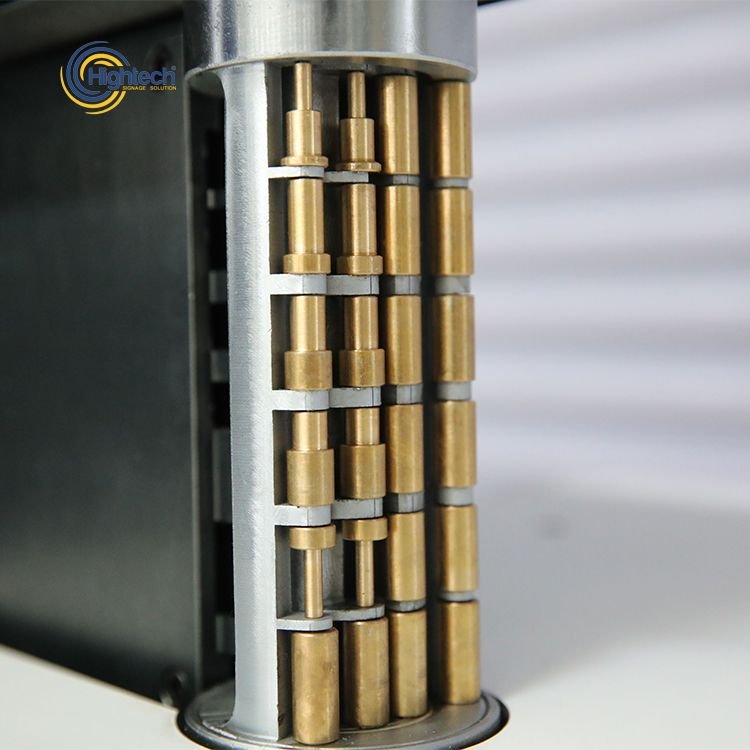

Dual Milling – Ensures consistent groove depth and precise bending quality across various materials. Copper Feeding – Double-row shaft minimizes friction and prevents scratches on delicate metal surfaces. Smart Calibration – Automatic depth adjustment delivers repeatable accuracy for complex bending operations. Material Versatility – Works seamlessly with aluminium, stainless steel, and Channelume profiles.Why Choose HT1-N

Precision Output – Maintains ±0.1 mm dimensional accuracy for professional channel letter manufacturing. Industrial Design – Built for stability, durability, and continuous 24/7 production environments. Seamless Workflow – Supports DXF, AI, and PLT files for efficient design-to-production transitions. High Efficiency – Accelerates bending speed and productivity while maintaining superior quality control.Applications

Signage Fabrication – Ideal for illuminated and non-illuminated channel letters in retail or branding projects. Architectural Use – Produces aluminium and stainless-steel profiles for high-precision decorative sign systems. Workshop Integration – Enables custom forming of trim-cap and Channelume materials for commercial sign workshops.Get Quote

Please share your company name, email address, and the product you are looking for