HTR5 CNC Router and Blade Cutters

Categories: CNC Routers And Blade Cutters, Machinery

- Warranty: 1year

- Sturdy Structure – Industrial-grade welded steel base for high stability; precision-machined XY-axis guide rails for durability and accuracy.

- High-Torque Spindle – 3.2 kW water-cooled spindle ensures precision even at high speeds.

- High-Speed Drive System – XYZ axes equipped with Lesai drives and 450A electronics for torque, speed, and long-term reliability.

- Precision Motion System – X/Y-axis 2.0 square linear guides + Z-axis TBI ball screw for accurate cutting.

- Rack & Pinion Drive – 1.25-module fine-ground gears ensure smooth high-speed operation.

- Advanced Control System – Industrial-grade, multi-window compatible with CAD/CAM software for efficient 3D carving/cutting.

- Stable Electronics – 3.0 kW inverter with military-grade EMI filtering for interference-free operation.

- Durable Worktable – Aluminum T-slot design, maintenance-free, compatible with all materials.

- Flexible Cable System – Shielded high-flex cables rated for 8M+ cycles, resistant to damage.

Product Gallery

Technical Parameters

| Work Area |

1300*2500mm ,3000*1500mm |

|---|---|

| Height of Material |

190mm |

| Duplicate targeting |

±0.025mm |

| Spindle power |

3.2KW water-cooled spindle |

| Working table |

Vacuum and Felt table |

| Operating mode |

758 servo drive and drive motor |

| Power |

AC220V±10% ,50HZ |

| Transmission mode |

Ground racks and square guides |

| Software operating environment and instructions |

Win10 system 64-bit |

| Tool shank diameter |

φ0.63 ,φ1 ,φ12.7 ,φ3.175 ,φ4 ,φ6 |

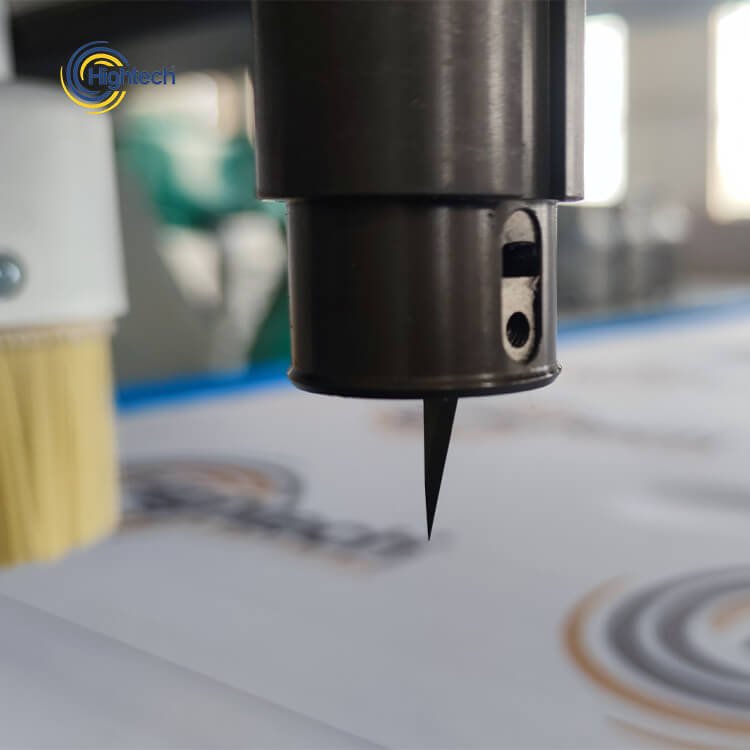

| Oscillating knife head |

20HZ high frequency up and down vibration cutting head |

Introducing HTR5 CNC Router and Blade Cutters

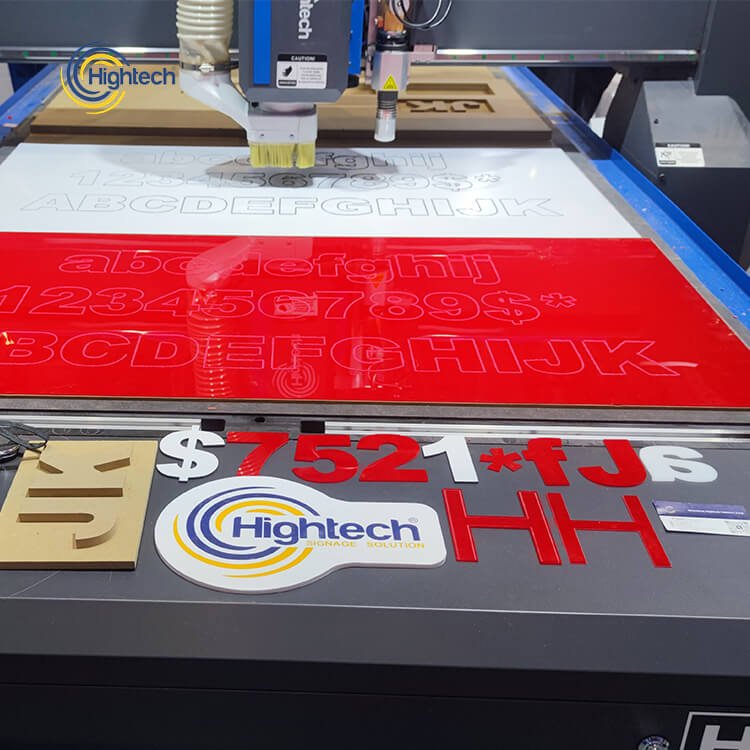

The HTR5 CNC Router and Blade Cutters is a powerful and versatile machine designed for precise engraving, cutting, and shaping of acrylic, PVC, wood, MDF, ACP, and KTboard. Featuring an advanced high-torque spindle motor, LEADSHINE drive system, and vacuum adsorption table, it ensures maximum accuracy, smooth operation, and long-lasting performance for professional applications. Ideal for businesses that require speed and precision in material processing.- Spindle Power: 3.2 kW water-cooled spindle

- Control System: Advanced DSP controller

- Drive System: LEADSHINE high-speed servo motor

- Table Type: T-slot aluminum alloy vacuum table

- Cooling System: Water-cooled spindle for consistent performance

- Voltage: Single-phase 220V / 50Hz

Key Features

- Robust Construction Industrial-grade design with high-quality steel frame ensures long-lasting stability and minimal distortion.

- High-Torque Spindle 3.2 kW water-cooled spindle for fast, high-precision cutting across multiple materials.

- LEADSHINE Drive System High-speed, high-torque performance with stable, reliable movement for precise processing.

- Advanced Vacuum System Efficient vacuum adsorption table holds materials securely without clamps for interference-free cutting.

Why Choose HTR5

- Powerful Spindle High-performance, water-cooled 3.2 kW spindle ensures clean, precise cuts every time.

- Stable Drive System The LEADSHINE high-speed drive offers large torque and high precision for efficient processing.

- Smooth Mechanical Transmission Precision rack and pinion transmission ensures smooth high-speed operation and minimal wear.

- Reliable Operation Anti-interference frequency conversion system guarantees stable machine performance under varying conditions.

Applications

- Signage & Lettering Perfect for creating intricate signs and channel letters from acrylic, PVC, and wood.

- Woodworking & Furniture Ideal for cutting and shaping MDF and wood components in furniture production.

- Industrial Panels Used for cutting ACP, KTboard, and polycarbonate for industrial and architectural applications.

Get Quote

Please share your company name, email address, and the product you are looking for