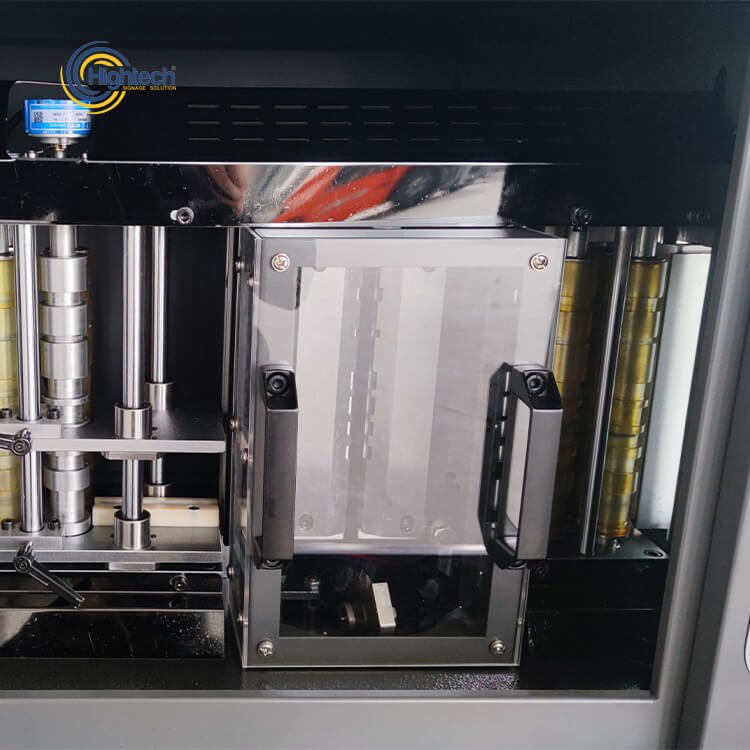

HT6 Channel Letter Bending Machine

Categories: Channel Letter Bending Machines, Machinery

- Perfect Letter Production – High-quality fabrication ensures flawless channel letters every time.

- Fully Automated Operation – Auto-feed, auto-slot, and auto-bend functions with adjustable cutting depth for seamless workflow.

- One-Cycle Computer Control – Single-button operation completes letter returns and outsides in one efficient cycle.

- High-Speed Production – Maximize efficiency with rapid fabrication, reducing downtime and boosting output.

- Precision Bending Technology – Ensures perfect alignment with CNC router-cut faces and backs for professional results.

- Massive Labor Savings – Replaces the production capacity of 10-20 manual workers, cutting costs significantly.

- Energy-Efficient Performance – Reduces power consumption while maintaining top-tier productivity.

- Universal Material Compatibility – Works with all standard aluminum materials for versatile fabrication.

- CE Certified – Guarantees top-quality, safety-compliant manufacturing for peace of mind.

Product Gallery

Technical Parameters

| Cutting Method |

Milling cutter |

|---|---|

| Bending Method |

Double rod linkage bending method |

| Feeding Method |

Rolling feeding device |

| Minimum bending angle |

R15mm |

| Cutting depth calibration |

Automatic by software |

| Applicable Material |

Channelume ,Extrusion Profile ,Flat Aluminum ,Korean Bar ,Metal Trim Cap |

| Height of Material |

20~180mm |

| Material Thickness |

0.3 ~1.2 mm |

| Size Accuracy |

±0.1mm Input |

| Input File Format |

AI ,DXF ,PLT |

| Power |

Single Phase ,AC220V±10% ,1KW ,55Hz |

| Air Source |

0.6 m3/min |

Introducing HT6 Channel Letter Bending Machine

The HT6 is designed to deliver precision, efficiency, and ease of use for modern signage production. Featuring automatic calibration and advanced software, it ensures consistent results for high-quality illuminated signage. Ideal for those looking to enhance production speed without sacrificing precision.- Automatic Calibration – Ensures precise and repeatable bends with minimal setup time.

- New Development & Software – Upgraded software increases efficiency and workflow optimization.

- Roller Feeding – High-accuracy, automatic feeding for smooth material handling.

- Easy to Operate – Simple interface and controls for faster training and productivity.

Key Features

Automatic Calibration – Ensures perfect bends every time, reducing human error. Upgraded Software – Optimized for efficiency and custom settings, enhancing workflow. Roller Feeding System – Guarantees smooth, consistent feeding with auto-straightening and cutting. Precision Cutting – 360° milling cutter supports accurate cuts at various angles.Why Choose HT6

Enhanced Productivity – Fast, accurate bending and feeding with minimal manual input. Durable Sensors – Photoelectric sensors from Japan for stable, long-lasting performance. Efficient Workflow – Auto-compensates for material variations, keeping bends precise. Versatile Materials – Handles Channelume, flat aluminum, and extrusion profiles with ease.Applications

Illuminated Signage – Ideal for creating vibrant, luminous letters for billboards and storefronts. Custom Bending – Supports a wide range of materials, including side-light Channelume and extrusion profiles. Billboard Production – Perfect for producing high-quality, durable illuminated signage at scale.Get Quote

Please share your company name, email address, and the product you are looking for