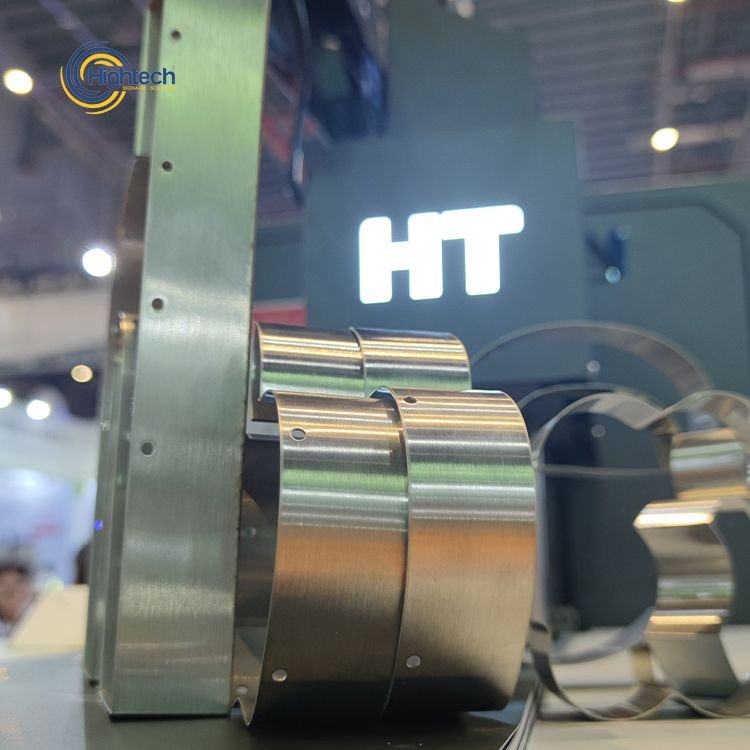

HT3 channel letter bending machine

Categories: Channel Letter Bending Machines, Machinery

- Unique Global Innovation – The only machine of its kind designed specifically for precision channel letter production.

- Fully Automated Process – Features automatic feeding, slotting, bending, and adjustable cutting depth for effortless operation.

- Intelligent One-Click Operation – Computer-controlled system completes Letter Returns/Outsides in one cycle with just the “Run” command.

- Unmatched Speed – Delivers rapid production to meet high-volume demands efficiently.

- Superior Precision – Ensures bent letter returns align perfectly with CNC-cut faces and backs.

- Reduced Labor Costs – Replaces the workload of 10-20 workers, dramatically lowering production expenses.

- Energy-Saving Design – Minimizes power usage without compromising performance.

Contains items: Complete machine + all accessories (computer/air compressor/spare parts) + tool box + training service

Product Gallery

Technical Parameters

| Feeding Method |

Circulation clamp feeding system |

|---|---|

| Slotting System |

Planer knife |

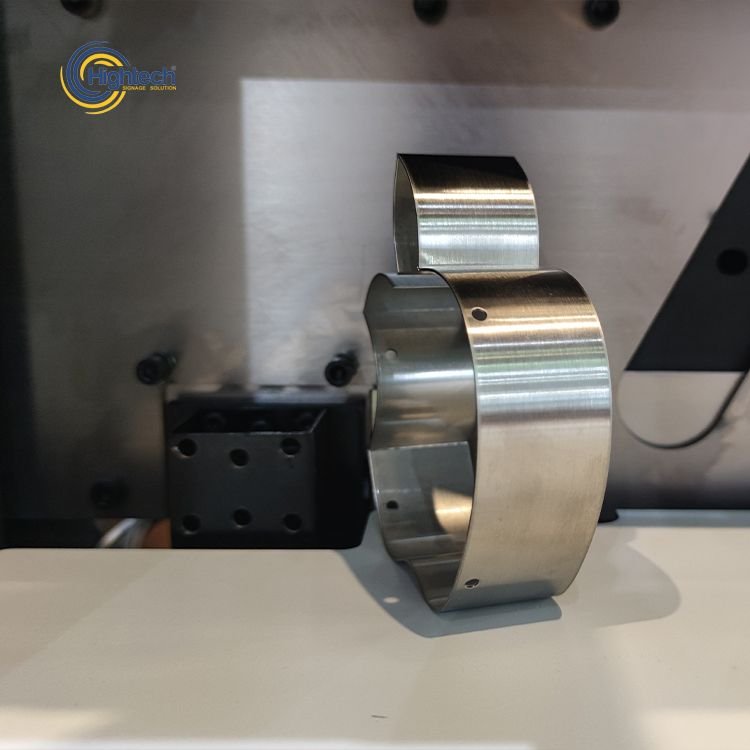

| Bending System |

Double blade alternate |

| Applicable Material |

Flat Aluminum ,Galvanized Strips ,Iron Strips ,Stainless Steel |

| Height of Material |

10~130mm & 10~220mm (Optional) |

| Material Thickness |

0.3~1.5mm |

| Minimum bending angle |

R7-8mm |

| Material of Height |

30~130mm |

| Size Accuracy |

±0.1mm Input |

| Input File Format |

DXF |

| Power |

Single Phase ,AC220V±10% ,2.4KW ,50HZ |

| Air Source |

0.6 m3/min |

Introducing HT3 Channel Letter Bending Machine

The HT3 is a next-generation bending solution engineered for stainless steel and flat aluminium channel letter fabrication. With intelligent calibration, upgraded software, and a double-blade alternate bending system, it offers unmatched precision, speed, and consistency in professional sign production.- Automatic Calibration – Guarantees bending accuracy and intelligent rebound compensation for complex curves.

- Planer Knife Slotting System – Dual-servo, encoder-controlled system for high-speed, high-precision slotting.

- Circulation Clamp Feeding – Ensures stable, accurate material feeding with minimal friction and surface damage.

- Optimized Efficiency – Intelligent structure and software upgrades boost productivity and reduce cutting costs.

Key Features

Precision Bending – Double-blade alternate system ensures smooth, accurate curves with rebound control. High-Speed Slotting – Dual-servo planer knife delivers consistent slotting accuracy with repeatable performance. Stable Feeding – Circulation clamp system and independent rack maintain reliable feeding stability. Durable Performance – Components support repeat grinding and extended tool life, minimizing maintenance.Why Choose HT3

Superior Accuracy – Maintains exceptional forming precision for stainless steel and flat aluminium materials. High Efficiency – Advanced servo and encoder systems significantly increase production speed. Smart Compensation – Automatically corrects bending rebound for flawless material shaping. Low Operating Cost – Regrindable blades and efficient slotting system reduce long-term production expenses.Applications

Stainless Steel Signage – Perfect for high-end channel letters requiring strong, polished finishes. Flat Aluminium Signs – Ideal for lightweight, luminous letters used in retail and building facades. Custom Fabrication – Supports decorative and architectural signage requiring durable precision bending.Get Quote

Please share your company name, email address, and the product you are looking for