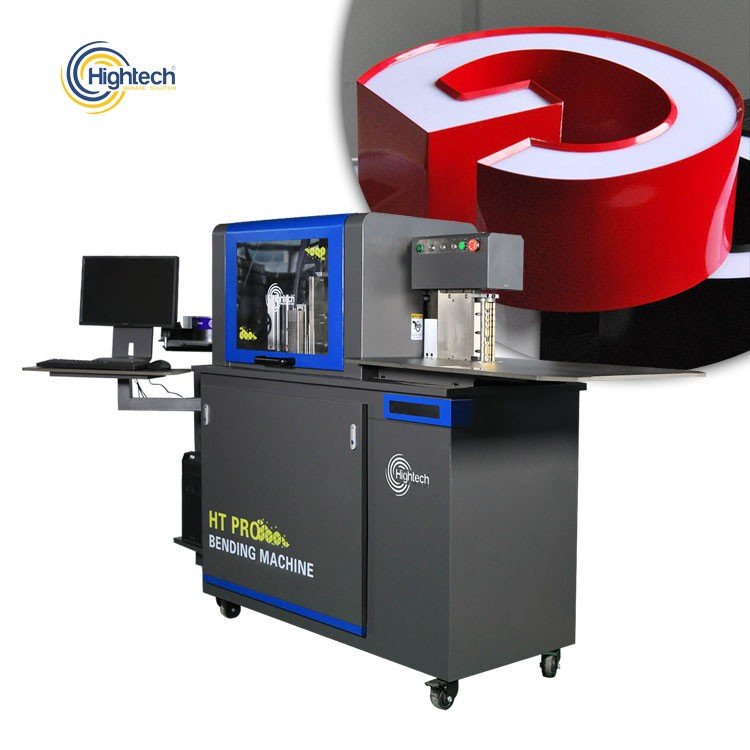

HT PRO channel letter bending machine

Category: Channel Letter Bending Machines

- Perfect machine for making professional channel letters worldwide.

- Fully automated operation: auto feed, auto slot, auto bend, and auto cutting depth adjustment.

- Computer-controlled system completes Letter Return/Outside with one click of “Run” button.

- High-speed production for maximum efficiency.

- Precision bending ensures perfect match to CNC router-cut faces and backs.

- Reduces labor costs – replaces 10-20 manual workers.

- Energy-efficient operation saves power costs.

- Compatible with stainless steel and all aluminum types.

- CE certified meeting European safety standards.

Product Gallery

Technical Parameters

| Warranty |

1year |

|---|---|

| Feeding Method |

Rolling feeding device |

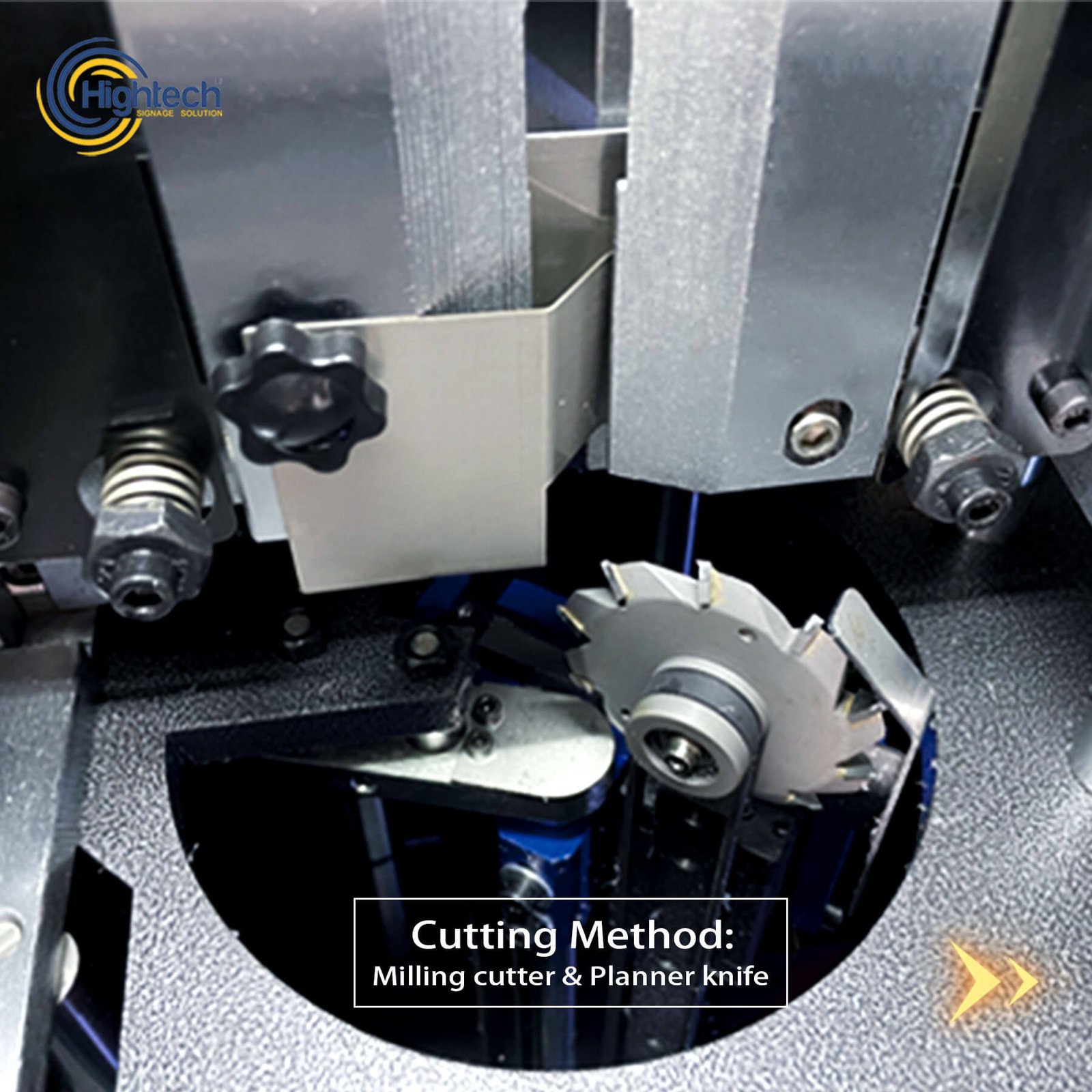

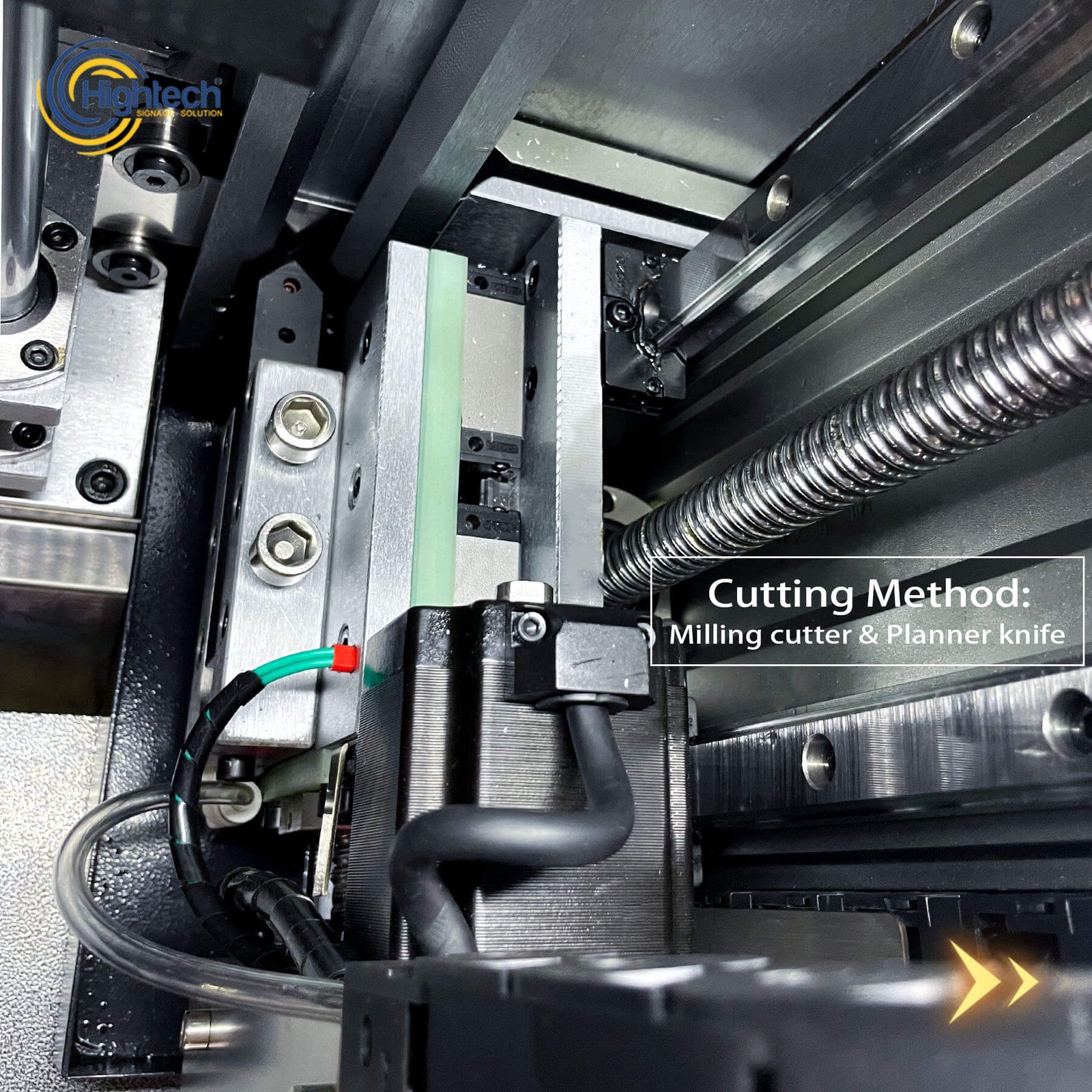

| Cutting Method |

Milling cutter ,Planner knife |

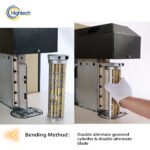

| Bending Method |

Double alternate blade ,Double alternate grooved cylinder |

| Applicable Material |

all type aluminum ,Galvanized Strips ,Stainless Steel |

| Minimum bending angle |

R10mm ,R6mm |

| Height of Material |

30~160mm |

| Material Thickness |

0.3~1.5mm |

| Input File Format |

AI ,DXF |

| Power |

Single Phase ,AC220V±10% ,2.4KW ,55Hz |

| Source |

0.6 m3/mi |

Introducing HT PRO Channel Letter Bending Machine

The HT PRO is a multifunctional, cost-effective bending machine that combines the precision of HT1 and HT3 models. Perfect for high-volume sign production, it handles a wide range of materials with ease. Designed for seamless operation and efficiency, it is ideal for creating durable and accurate illuminated signage.- Double Bending System – Flexible double alternate cylinders and blades ensure versatility with material changes.

- Roller Feeding – Independent material rack provides stability for consistent feeding and smooth operations.

- Precision Cutting – 360° adjustable milling cutter and planer knife create precise cuts and slots at various angles.

- Budget-Friendly – Offers high performance at an affordable price, ideal for businesses with tight budgets.

Key Features

Double Bending System – Alternating cylinders and blades allow quick material changes without additional testing. Roller Feeding Mechanism – Stable material feeding with independent rack for improved accuracy. Multifunctional Operation – Combines features of HT1 and HT3 models, offering versatile functionality. 360° Cutting Precision – Automatic adjustment for slot depth and angle, ensuring perfect cutting every time.Why Choose HT PRO

Cost-Effective Solution – Combines the best features of HT1 and HT3 at a budget-friendly price. Versatile Materials – Supports Channelume, stainless steel, flat aluminum, and more. Efficient Operation – Simplifies material replacement and setup for fast, continuous production. Advanced Cutting System – Flexible milling cutter with 360° rotation for detailed cuts and slots.Applications

Signage Production – Ideal for creating durable, illuminated channel letters for commercial signs. Material Flexibility – Works with a wide range of materials, from aluminum to stainless steel. High-Volume Production – Perfect for businesses needing fast, accurate sign fabrication at scale.Get Quote

Please share your company name, email address, and the product you are looking for