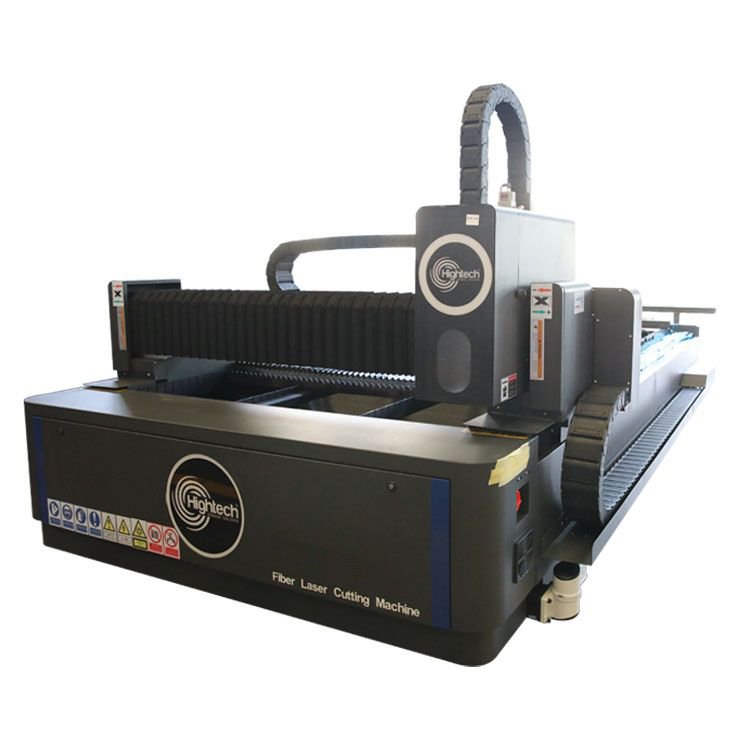

HT FC-2040 Exchange Table Fiber Laser Cutting Machine

Categories: Fiber laser Cutting Machine, Machinery

- High-quality fiber laser source and head for exceptional beam quality and power stability, with maintenance-free operation

- Runs on air, oxygen, or nitrogen, providing flexible cutting options for different materials

- Industrial-strength construction with three-axis dust-proof design, XY-axis rack drive, and Z-axis screw drive

- Precision servo system with high-stability electronic components for accurate and reliable performance

- Auto-focus laser head with capacitive height control for automatic adjustment to plate variations

Product Gallery

Technical Parameters

| Warranty |

1year |

|---|---|

| Weight |

1200Kg |

| Power |

Single Phase ,AC220V±10% ,50HZ |

| Outlinesize |

3900.5*2760*1650mm |

| X-axis Travel |

2000mm |

| Z-axis Travel |

80mm |

| Work Area |

2000*4000mm |

| Protection Level of Total Powersupply |

IP54 |

| Maximum acceleration |

0.4G |

| Repeated positioning |

±0.02mm |

| Applicable Material |

Aluminum alloy ,Brass ,Carbon Steel ,Copper ,Electrolytic Sheet ,Galvanized sheet ,Manganese Alloy ,Silicon Steel ,Stainless Steel ,Titanium Alloy |

| Table maximum load |

700Kg |

| Positioning Accuracy |

±0.05mm |

| Cutting Speed |

60m/min |

HT FC-2040 Exchange Table Fiber Laser Cutting Machine

The HT FC-2040 Exchange Table Fiber Laser Cutting Machine is a high-efficiency industrial fiber laser system designed for fast and precise cutting of a wide range of metal sheets. Featuring fully automatic focusing, intelligent tracking, and free nesting technology, it is ideal for industries requiring continuous production and high throughput. The exchange table design enables rapid material replacement, maximizing productivity and minimizing downtime.Key Highlights

- Exchange Table System: Allows quick material swaps for uninterrupted workflow.

- Automatic Focusing & Tracking: Maintains accuracy across varying sheet thicknesses.

- Industrial-Grade Build: High-strength annealed bed and aviation-grade aluminum beams ensure stability.

- Advanced Control System: FSCUT system with precise power monitoring and smooth motion control.

Key Features

- Precision Transmission: YYC guide rails and helical rack drive provide accurate and smooth movement while reducing driving torque.

- Durable Machine Bed: 600°C high-temperature annealed bed ensures rigidity, vibration resistance, and long-term stability.

- Laser Components: Raycus laser source paired with Raytools cutting head delivers stable beam quality and fast cutting speeds.

- Cooling System: Hanli water chiller provides reliable cooling, efficient heat exchange, and laser protection during long operation cycles.

Why Choose HT FC-2040

- High Productivity: Exchange table reduces downtime, enabling continuous cutting operations and higher throughput.

- Superior Accuracy: Automatic focusing and intelligent tracking guarantee precise cuts on complex designs.

- Robust & Durable: Heavy-duty frame and reinforced aluminum beams minimize vibration and maintain alignment under demanding workloads.

- User-Friendly Operation: FSCUT control system simplifies parameter adjustments, monitoring, and safe operation.

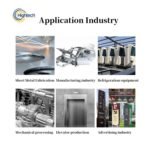

Applications

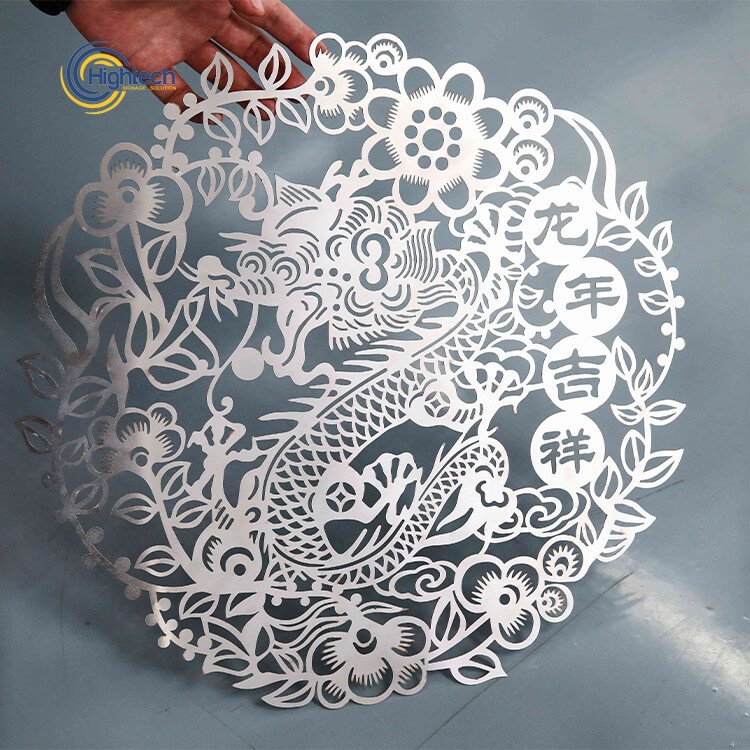

- Sheet Metal Fabrication: Cuts carbon steel, stainless steel, aluminum, galvanized sheets, and other metal alloys.

- Industrial Manufacturing: Suitable for machinery components, refrigeration equipment, and mechanical processing.

- Construction & Elevators: Precision cutting for structural metal panels and elevator parts.

- Advertising & Signage: Efficient cutting for industrial signs, decorative panels, and custom metal lettering.

Get Quote

Please share your company name, email address, and the product you are looking for