Blog

How a nitrogen generator works?

Table of Contents

In many industries, nitrogen plays a critical role in ensuring product quality, preventing oxidation, and creating safe operating environments. A Nitrogen Generation System allows businesses to produce high-purity nitrogen directly on-site, eliminating the need for delivered gas cylinders or tanks. This not only saves costs but also provides greater reliability and control over gas supply.

What Is a Nitrogen Generator?

A nitrogen generator is a machine that separates nitrogen from atmospheric air, providing a continuous and controllable supply of high-purity nitrogen. Air naturally contains roughly 78% nitrogen, but a generator removes oxygen, moisture, and other gases to deliver nitrogen at purity levels that meet industrial standards.

These generators are essential in sectors where precise nitrogen control is required, including food and beverage packaging, pharmaceuticals, electronics, chemical processing, and metal fabrication. By producing nitrogen on-demand, businesses gain cost savings, operational flexibility, and reduced downtime compared to traditional cylinder-based supplies.

Key functions include:

- Air Separation: Removes oxygen, moisture, and other gases from compressed air to produce nitrogen.

- On-Demand Supply: Provides nitrogen as needed, reducing storage requirements and minimizing downtime.

- Purity Control: Maintains consistent nitrogen purity levels to meet industry-specific standards.

- Cost Efficiency: Reduces cylinder procurement, delivery, and handling expenses.

- Operational Flexibility: Easily integrates with production lines for continuous or intermittent nitrogen use.

How Does a Nitrogen Generator Work?

A nitrogen generation system works by separating nitrogen from the other components of air, primarily oxygen and moisture. This process ensures a reliable supply of high-purity nitrogen for industrial applications without the need for storage tanks or cylinder deliveries.

Modern systems are designed for efficiency, consistency, and minimal maintenance, allowing businesses to reduce operating costs while improving process control.

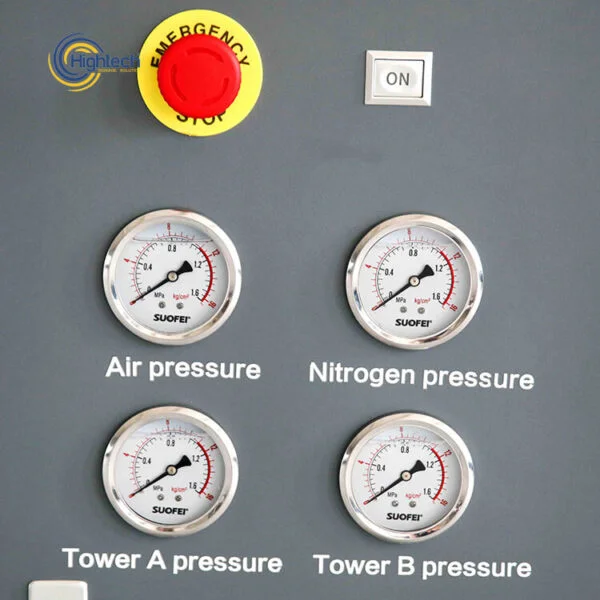

Nitrogen Generation System

A nitrogen generation system typically uses filtration, adsorption, or membrane technology to extract nitrogen. It can operate continuously, providing a stable flow of gas for manufacturing, packaging, or laboratory processes.

Membrane Nitrogen Generators

Membrane generators use selective permeable membranes to separate nitrogen from oxygen. They are compact, energy-efficient, and ideal for moderate nitrogen purity needs, usually up to 99%.

Pressure Swing Adsorption (PSA) Nitrogen Generators

PSA generators utilize carbon molecular sieves to adsorb oxygen under pressure, delivering very high-purity nitrogen, often exceeding 99.99%. PSA systems are widely used where ultra-pure nitrogen is critical, such as in electronics and pharmaceuticals.

Industrial Applications of Nitrogen Generators

Nitrogen generators play a crucial role in industries that require a reliable, high-purity gas supply. By producing nitrogen on-site, businesses can improve production efficiency, maintain product quality, and reduce dependency on cylinder or liquid nitrogen deliveries. These systems are versatile, allowing tailored nitrogen purity levels and flow rates for specific industrial applications. Their use minimizes material waste, ensures safety, and supports regulatory compliance across sectors.

Food Packaging

Nitrogen displaces oxygen inside packaging, preventing spoilage and extending the shelf life of products such as snacks, meat, and baked goods. It ensures freshness while reducing the need for chemical preservatives, enhancing both quality and safety.

Electronics Manufacturing

In electronics production, nitrogen creates an inert atmosphere during soldering and assembly. This prevents oxidation of sensitive components, ensures reliable connections, and improves overall device performance.

Pharmaceutical Industry

Nitrogen is essential for drug manufacturing, packaging, and storage. It maintains sterility, reduces oxidation, and ensures that sensitive formulations remain stable, meeting strict regulatory standards.

Metal Fabrication and Welding

Using nitrogen during welding and metal fabrication protects molten metals from oxidation, controls heat-affected zones, and reduces warping. It improves welding quality for materials such as stainless steel, aluminum, and carbon steel.

Chemical Processing

Nitrogen acts as a protective blanket over reactive chemicals, preventing unwanted reactions and reducing fire or explosion risks. This ensures consistent product quality and safer handling in chemical manufacturing.

the global leader in channel letter bending machines and equipment

Hightech Industry Group

Advantages of On-Site Nitrogen Generation

Producing nitrogen on-site provides industries with greater control, efficiency, and cost savings compared to traditional gas delivery methods. By generating nitrogen as needed, businesses reduce dependency on cylinder supplies, avoid downtime, and ensure a consistent, high-purity gas flow tailored to their applications.

- Cost Savings: Eliminates frequent cylinder deliveries and associated transport costs, reducing overall operating expenses.

- Reliable Supply: Continuous on-demand production ensures no interruptions in critical processes.

- High Purity Control: Systems can be adjusted to meet specific purity requirements for different industrial needs.

- Safety and Convenience: Reduces storage risks of high-pressure cylinders and minimizes handling hazards.

- Environmental Benefits: Produces nitrogen without chemical use or excess waste, promoting eco-friendly operations.

Choosing the Right Nitrogen Generator

Selecting the appropriate nitrogen generator depends on your industry’s specific requirements, including desired purity, flow rate, and application type. Evaluate whether your processes need continuous high-purity nitrogen or moderate purity for general use, as this will determine the choice between membrane and PSA systems. Consider the generator’s capacity, footprint, energy efficiency, and ease of maintenance. Additionally, factor in long-term costs, reliability, and the availability of support and training to ensure smooth operation. Choosing the right system guarantees consistent performance, cost efficiency, and operational safety.