Blog

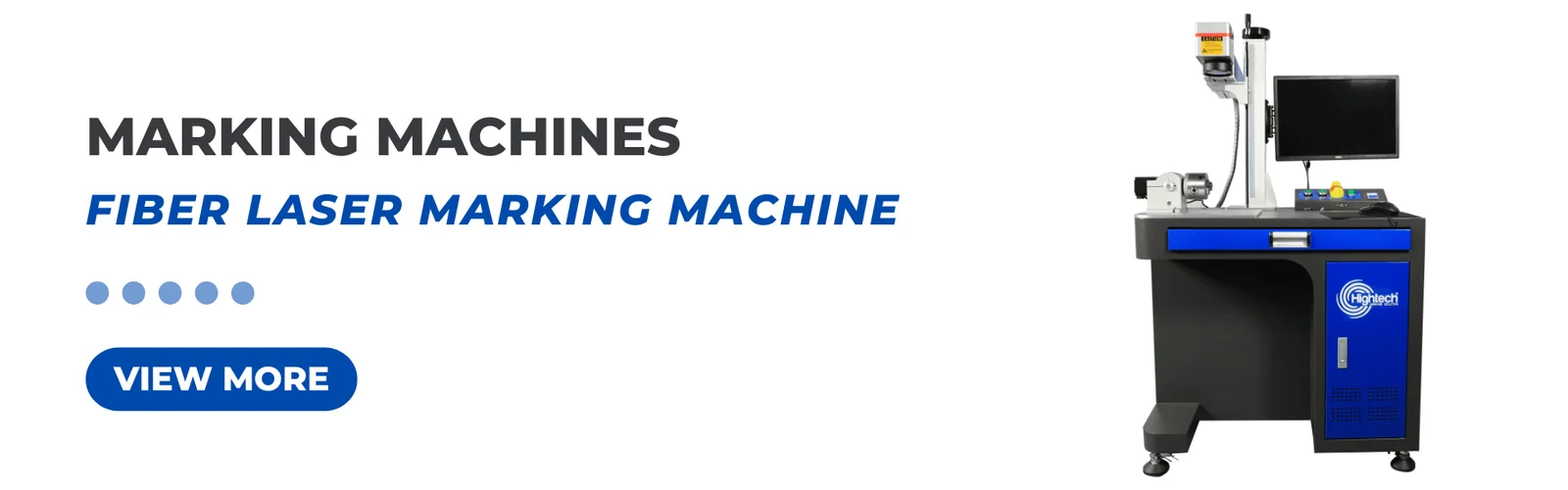

What a Fiber Laser Marking Machine Can Do For You?

Table of Contents

Fiber laser marking offers precise, permanent, and ink-free identification across a wide range of materials. Using a focused fiber laser, manufacturers etch serial numbers, barcodes, logos and traceability data with minimal heat impact and without consumables.

This fast, low-maintenance method improves production consistency, supports regulatory traceability in medical and automotive sectors, and enhances brand presentation on metals, plastics and composites.

What Is Fiber Laser Marking?

Fiber laser marking is a high-precision method that uses a focused laser beam to engrave, etch, or mark various materials. Unlike traditional marking methods, it doesn’t require ink or physical contact.

The laser beam interacts with the surface, creating permanent, high-contrast marks such as text, serial numbers, barcodes, or logos. This process ensures durability, resistance to fading, and exceptional clarity even on complex materials.

How Does Fiber Laser Marking Work?

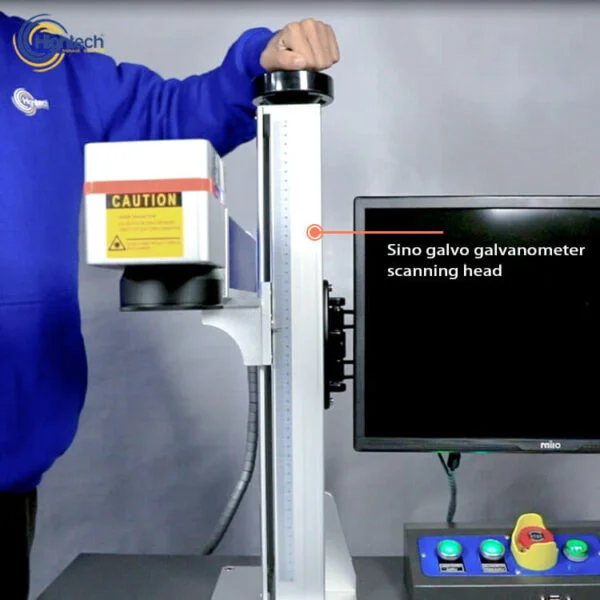

Fiber laser marking systems generate a concentrated beam of light by passing photons through a fiber optic cable doped with rare-earth elements like ytterbium. This beam is then directed through a lens to the work surface.

The laser’s energy alters the surface material through:

- Annealing: Creating oxidation layers for smooth, dark marks.

- Etching or Engraving: Removing layers for deeper, visible marks.

- Foaming: Producing light, raised marks on plastics.

The result is a clean, precise mark with minimal thermal distortion, ideal for mass production and delicate components.

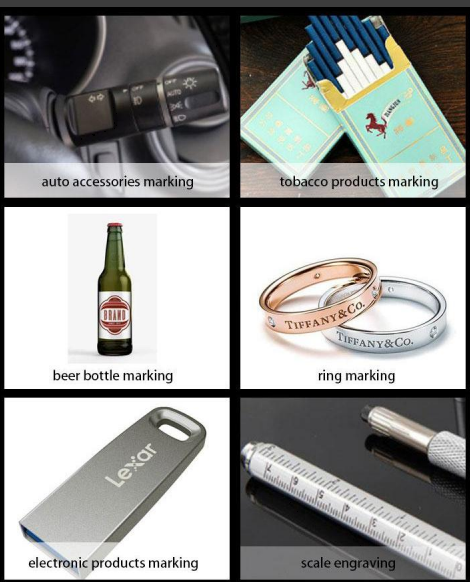

Industrial Applications of Fiber Laser Marking Machine

Fiber laser marking machines have become essential tools across modern industries thanks to their precision, speed, and versatility. From large-scale manufacturing to fine-detail engraving, they ensure permanent, high-quality identification without damaging materials. Businesses use them to mark logos, barcodes, serial numbers, and compliance codes—boosting traceability, product authenticity, and brand value.

Fiber Laser Marking in the Automotive Industry

In automotive manufacturing, precision is key. Fiber laser marking machines are used to label engine parts, chassis numbers, sensors, and interior components. They provide durable markings that can withstand heat, oil, and friction—essential for safety and traceability.

Integrated Circuit Industry

In the semiconductor and IC industries, fiber lasers mark micro components, circuit boards, and chips. The fine laser beam ensures accuracy on tiny surfaces without damaging sensitive elements.

Electronics Industry

From smartphones to home appliances, fiber laser marking ensures traceability and branding. The process allows QR codes, serial numbers, and company logos to be engraved clearly on plastic and metal housings.

the global leader in channel letter bending machines and equipment

Hightech Industry Group

Why Fiber Laser Marking Is a Must in the Medical Industry

Medical tools and implants require permanent, sterile, and biocompatible marks. Fiber lasers engrave surgical instruments, syringes, and implants without chemical additives, meeting FDA and UDI (Unique Device Identification) requirements.

Jewelry and Accessories Industry

For jewelry, watches, and luxury items, fiber laser marking provides ultra-fine engraving with perfect detail. Logos, serial codes, or custom designs can be applied to gold, silver, and stainless steel surfaces, adding authenticity and elegance.

What Kind of Material Can Be Marked by a Fiber Laser Marking Machine?

One of the greatest advantages of fiber laser marking is its versatility. It works on a wide range of materials, including:

- Metals: Stainless steel, aluminum, brass, copper, titanium.

- Plastics: ABS, PVC, polycarbonate.

- Ceramics and Silicon.

- Carbon Fiber and Composites.

This flexibility makes it ideal for industries ranging from aerospace to consumer electronics.

Marking Metals with Fiber Laser: Fast, Clean, Reliable

When it comes to metals, fiber lasers deliver unmatched precision and consistency. The process produces sharp, readable marks that resist corrosion and wear.

Applications include marking industrial tools, electronic housings, and machine components. Compared to mechanical engraving, it’s faster, contact-free, and virtually maintenance-free.

Marking Plastics with Fiber Laser: Clean, Clear, and Reliable

Plastic marking requires careful control of laser parameters to prevent melting or deformation. Fiber lasers use low-heat marking modes to produce crisp, non-damaging results on polymers. This is especially useful for electronic casings, automotive dashboards, and packaging components.

Carbon Fiber

Carbon fiber materials are strong yet sensitive to heat. Fiber lasers mark them efficiently without causing delamination or weakening the structure. This capability is increasingly important in aerospace, automotive, and sports equipment manufacturing.

Some Special Uses of Fiber Laser Marking Machines

Beyond traditional industrial applications, fiber laser marking machines are also used for advanced and creative purposes. Their ability to produce deep, colored, or high-contrast marks allows manufacturers and designers to achieve unique visual effects on metals and other materials.

These specialized applications—such as black marking on aluminum or color marking on stainless steel—help enhance aesthetics, improve product differentiation, and meet branding or compliance needs. In sectors like luxury goods, electronics, and aerospace, such precision detailing makes fiber laser marking an irreplaceable technology.

Black Marking on Aluminum

By adjusting frequency and pulse duration, fiber lasers create deep black markings on anodized or raw aluminum surfaces. This technique is widely used for branding, serial numbers, and high-end product finishes.

Color Marking on Metal

Advanced fiber lasers can produce colored oxide layers on stainless steel and titanium, creating rainbow-like patterns. These aesthetic color marks are popular in decorative metalwork and premium branding.

Black Marking on Metal

Through controlled oxidation, fiber lasers generate matte black marks on metals without altering the surface texture—ideal for parts requiring high legibility and contrast.

How to Choose the Right Fiber Laser Marking Machine?

Selecting the right machine depends on several factors:

- Material Type: Different models are optimized for metals, plastics, or mixed materials.

- Laser Power: Ranges from 20W to 100W; higher wattage enables deeper, faster marking.

- Marking Area: Choose a lens size that matches your product dimensions.

- Software Compatibility: Ensure the system supports vector graphics, barcodes, and automation features.

- After-Sales Support: Reliable maintenance and technical training are key for long-term performance.

A good strategy is to test your material samples before purchase to ensure marking quality and contrast.

Final Thoughts: What You Really Need to Know About Fiber Laser Marking

Fiber laser marking technology offers a clean, efficient, and highly adaptable solution for permanent marking needs. Its ability to work on metals, plastics, and composites—without consumables or extensive maintenance—makes it a long-term investment for modern manufacturing. Whether for traceability, branding, or decorative applications, the fiber laser marking machine delivers precision, speed, and durability unmatched by traditional methods.