Blog

Why Laser Welding is the First Choice for Precision Projects?

Table of Contents

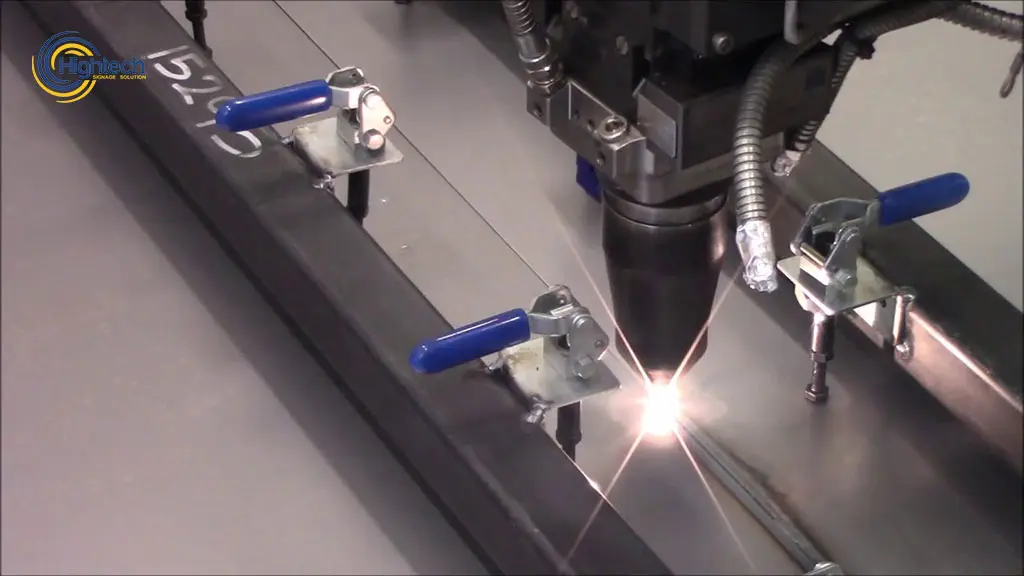

Why is laser welding the best choice for high-precision projects? In industries requiring high-precision, the choice of welding technology plays a critical role in product quality and efficiency. Laser welding stands out as the best option for high-precision projects because it provides unparalleled accuracy, speed, and minimal material distortion. These factors are essential for manufacturing industries that deal with delicate parts, small components, and intricate designs.

This article explores why laser welding for precision projects is increasingly in demand, outlines its key advantages, and compares it to traditional welding methods. We will also examine the industries that benefit the most from laser welding and how it ensures superior results in demanding applications.

Laser welding provides exceptional precision and accuracy for high-precision projects, with minimal material distortion and fast production. It’s ideal for industries like aerospace, medical, and electronics.

Why Laser Welding Demand is Rising for High-Precision Projects?

The demand for laser welding for precision projects has been steadily increasing across multiple industries due to its unmatched ability to deliver high-quality, reliable, and efficient welds. Modern manufacturing increasingly requires components with tight tolerances and minimal defects, and traditional welding methods such as MIG or TIG often struggle to meet these stringent requirements. Laser welding addresses these challenges by combining precision, speed, and repeatability, making it an essential tool for sectors where quality cannot be compromised.

Several factors are driving this growing demand:

- Precision and Consistency: Laser welding produces consistent welds with minimal human error, ensuring every joint meets exact specifications.

- Minimal Heat-Affected Zone: The focused energy input reduces thermal distortion, maintaining the integrity of delicate or thin materials.

- Speed and Efficiency: Laser welding is significantly faster than traditional methods, which accelerates production cycles and lowers labor costs.

- Versatility: It can be used across a wide range of metals and thicknesses, from aluminum to stainless steel, accommodating diverse industrial applications.

- Suitability for Complex Parts: Laser welding easily handles intricate geometries, tight corners, and hard-to-reach areas, which are challenging for conventional techniques.

Industries such as medical devices, electronics, aerospace, and automotive increasingly rely on laser welding to achieve the precision required for high-performance applications. With the rise of advanced 3D-printed components and microfabrication, laser welding offers the capability to maintain accuracy without compromising structural integrity.

This combination of precision, efficiency, and adaptability makes laser welding not just a preferred choice but a necessity for manufacturers focused on high-precision, high-quality production.

What Are the Key Advantages of Laser Welding for Precision Projects?

laser welding efficiency is transforming high-precision manufacturing by offering numerous advantages over traditional welding methods. It is particularly valued in industries where accuracy, speed, and minimal material distortion are critical. The following key advantages make laser welding the preferred choice for precision projects:

Superior Accuracy and Consistency

One of the most compelling laser welding advantages for precision projects is its unmatched accuracy and consistency. The concentrated laser beam can be precisely controlled, enabling it to make extremely fine, accurate welds. This high level of precision is ideal for creating small, intricate joints, which would be challenging to achieve with traditional welding methods like MIG or TIG welding. The ability to control the laser’s focus also ensures consistent results across multiple parts, making it ideal for high-volume production where uniformity is essential.

Minimal Material Distortion

Unlike traditional welding processes that generate significant heat, laser welding operates with minimal thermal input. This results in much lower material distortion. By focusing the heat only on the welding area, laser welding reduces the heat-affected zone (HAZ), which is the part of the material that is affected by the welding heat. In turn, this leads to less warping and shrinkage of the material, maintaining the integrity and precision of the components. For industries like aerospace and electronics, where tight tolerances are crucial, laser welding is the go-to solution for reducing material distortion.

Fast and Efficient Production

Laser welding is not only precise, but it’s also fast and efficient. The speed of laser welding significantly improves production times when compared to traditional methods. With laser welding machines operating at high speeds, manufacturers can process large batches of parts in less time, increasing productivity. Furthermore, laser welding can be easily automated, allowing for continuous operation without sacrificing quality. For industries where time-to-market is important, this level of efficiency provides a competitive edge, reducing overall labor costs and production delays.

Flexibility Across Metals and Thicknesses

Laser welding is highly versatile and can be used on a wide range of materials, including steel, aluminum, titanium, and even more specialized materials such as stainless steel and precious metals. Whether the material is thin or thick, laser welding offers flexibility in handling different material types and thicknesses. This versatility makes it the ideal solution for industries such as automotive, medical devices, and electronics, where various materials must be welded with precision. The process can be easily adjusted to accommodate different types of alloys or material thicknesses, further expanding its utility across various manufacturing sectors.

What Are the Key Applications of Laser Welding in Precision Projects?

laser welding applications is a game-changer in industries that require high levels of precision. Its ability to create clean, consistent, and reliable welds in challenging materials has made it the preferred choice for many manufacturing sectors. Below are the key industries and projects that benefit the most from laser welding for precision projects.

Medical Devices and Precision Instruments

Laser welding is critical in the medical device industry, where precision and cleanliness are essential. Laser welding ensures that intricate components such as surgical instruments, implants, and medical tubing are assembled with minimal distortion and perfect precision. The technology’s clean operation also helps avoid contamination, a key factor in medical applications.

Aerospace and Defense

In the aerospace and defense industries, components must meet extremely high standards of quality and reliability. Laser welding plays a vital role in manufacturing aircraft parts, engine components, and other critical assemblies. It ensures that joints are strong, precise, and capable of withstanding the stresses encountered during flight or military operations.

Electronics and Microfabrication

Laser welding is essential in the electronics industry, particularly in microfabrication. It is used for assembling small, complex electronic components like printed circuit boards (PCBs) and connectors. The precision of laser welding allows for small parts to be joined with accuracy, without causing damage to sensitive materials or creating thermal damage.

Automotive and High-Precision Parts

In the automotive industry, laser welding is used for joining lightweight materials such as aluminum and high-strength steel. This is especially important for high-precision automotive components, including body panels, frames, and intricate parts where weight reduction and strength are critical. Laser welding ensures strong, precise welds, enhancing vehicle performance and safety.

Advanced 3D-Printed Components

Laser welding is also making strides in the world of 3D printing, where precision is paramount. In industries that use 3D-printed parts, such as aerospace and automotive, laser welding is used to join 3D-printed metal parts with exceptional accuracy. This technology enables the production of complex geometries and high-quality metal joins for 3D-printed structures.

Precision Comparison: Laser Welding vs Traditional Welding Methods

When comparing laser welding to traditional welding methods like TIG and MIG, it’s clear that laser technology offers distinct advantages, particularly in precision, speed, and minimal material distortion. The following table summarizes key differences between laser welding and traditional methods.

Feature | Laser Welding | TIG Welding | MIG Welding |

Precision | Superior precision and consistency, especially for small components | High precision but can be challenging for thin materials | Less precise, especially for intricate parts |

Speed | Fast and efficient with minimal heat input | Slower compared to laser welding due to manual intervention | Faster than TIG but still slower than laser welding |

Material Distortion | Minimal material distortion due to lower heat input | More distortion, especially on thin materials | More distortion due to higher heat input |

Versatility (Materials) | Effective on a wide range of metals and thicknesses | Limited by the skill of the welder and material thickness | Works on a variety of materials but lacks precision on thin metals |

Operating Cost | Higher initial investment but lower long-term costs | Relatively low setup cost but slower production | Moderate setup cost with less efficiency |

Ease of Use | Requires skilled operators but automated systems help | Requires high skill for precision welding | Easier to use but less accurate in fine details |

Laser Welding vs TIG Welding

- Laser welding provides higher precision and faster speeds than TIG welding. The focused laser beam produces clean, accurate welds with minimal heat distortion, making it ideal for small, delicate components.

- TIG welding, while accurate, involves more manual effort and can create more heat-affected zones, leading to material distortion. It is best suited for thicker materials, while laser welding is effective even on thin sheets or complex geometries.

Laser Welding vs MIG Welding

- Laser welding excels in precision and is much faster than MIG welding, which is ideal for general-purpose applications but not for fine details. MIG welding can lead to more material distortion, especially when working with thin materials.

- MIG welding has the advantage of being more widely used in heavy-duty applications but falls short in industries requiring high-precision joins or those involving small parts.

Take Your Precision Projects to the Next Level with HT Industry Co

Choosing the right equipment is essential to achieving the best results for high-precision welding projects. HT Industry Co offers advanced laser welding systems that ensure unmatched precision, speed, and reliability.

Whether you’re dealing with complex components or require microscopic welds, HT Industry Co’s laser welding machines provide the performance you need to take your manufacturing to the next level.

Frequently Asked Questions

1. Why is laser welding the best choice for precision projects?

Laser welding is the best choice for precision projects due to its exceptional accuracy, minimal heat distortion, and high-speed production.

2. Is laser welding faster while still maintaining high precision?

Yes, laser welding is significantly faster than traditional methods, and it maintains the same level of high precision, making it ideal for time-sensitive, high-quality projects.

3. What are the advantages of laser welding over other methods?

Laser welding offers superior precision, minimal material distortion, and faster production speeds, making it ideal for industrial laser welding like aerospace and electronics.

4. Can laser welding handle small or delicate components without errors?

Yes, laser welding is ideal for small or delicate components, as it minimizes heat input and ensures clean, precise joins without damaging the surrounding material.

2 thoughts on “Why Laser Welding is the First Choice for Precision Projects?”

The focus on high-precision applications really highlights why laser welding is so valuable. I found a related discussion on https://tinyfun.io/game/noobs-are-coming that touched on the importance of accuracy in similar technical fields.

Hi,Thank you for reaching out Hightech,we will check!