4 in 1 Fiber Laser Welding machine HT FW 1500

Categories: 4 in 1 Fiber Laser Welding Machine, Laser Welding Machines

Product Gallery

Technical Parameters

| Warranty |

1year |

|---|---|

| Optical Fiber Laser |

Maxphotonics Industrial Edition |

| Chiller |

Huaku ,S&A Chiller |

| Control system |

built-in craft package easy to get started ,Supporting system |

| Machine Cabinet |

Hightech, industrial-grade anti-jamming cabinet |

| Weight |

215Kg |

| Wire Feeder |

Double-drive wire feeder ,preciseand adjustable speed ,smooth wire feeding |

| Power |

Single Phase ,AC220V±10% ,50HZ ,60Hz |

| Welding thickness |

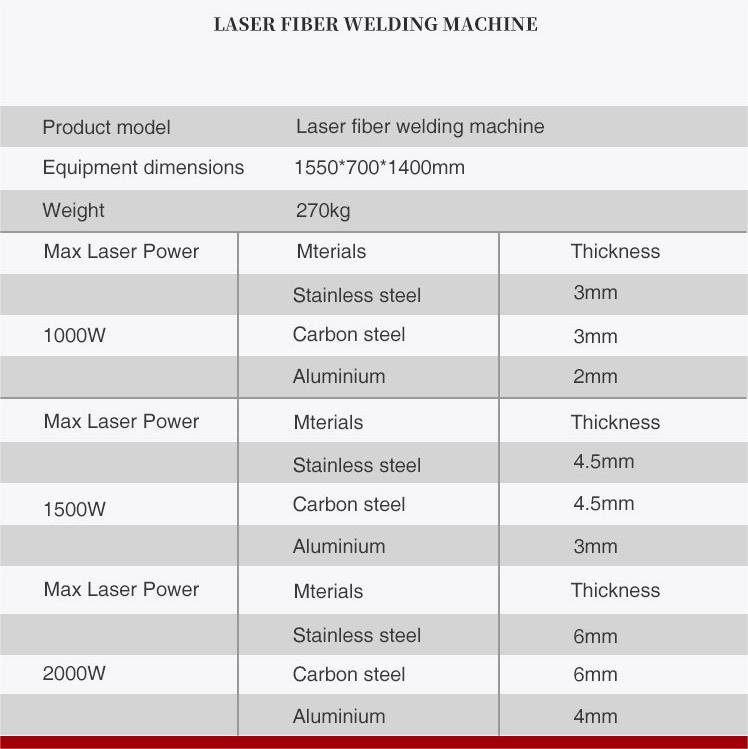

1500W: Stainless steel: 4mm, Carbon steel: 4mm, Aluminium: 3mm |

| Put the environment |

Flat, with no vibration or impact |

| Working environment |

10~40℃ ,humidity: ≤70% |

| Cooling Method |

Hydrocooling |

| Laser wave length |

1064nm (±10nm) |

| Applicable power (W) |

≤1500W |

| Collimator Specification (mm) |

D16-F60 |

| Focus mirror size (mm) |

120- F150 |

| Focus vertical adjustment range (mm) |

±10mm |

| Scan width-Welding |

F150-0~30mm ,F400-0~60mm ,F800-0~120mm |

| Protective mirror size (mm) |

D18xT2 |

| Gun body air pressure (Bar) |

≤15Bar |

Introducing 4 in 1 Fiber Laser Welding machine HT FW 1500

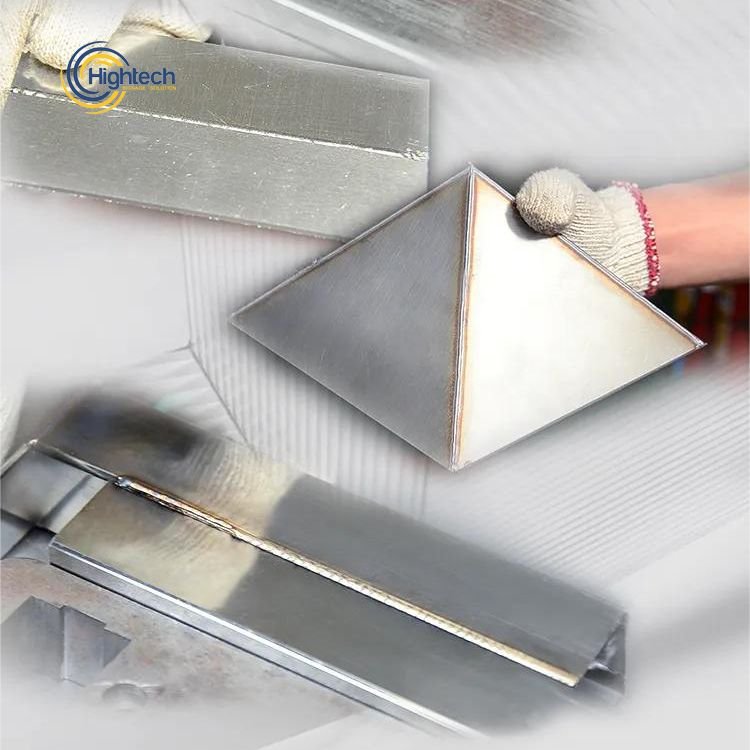

The HT FW-1500 4-in-1 Fiber Laser Welding Machine is a compact, high-precision system built for smooth, efficient, and versatile metal welding. Supporting overlap, spot, butt, tower, edge, and T-welds, it delivers clean seams with no secondary grinding required. Its ergonomic handheld gun, integrated cooling system, and stable fiber laser source make it ideal for workshops, fabrication units, and industrial production environments.Key Highlights

- 4-in-1 Multi-Weld Support: Handles spot, butt, overlap, tower, edge, and T-weld applications.

- Fast & Efficient: Welding speed up to 2–10× faster than traditional electric welding.

- Clean, Smooth Finish: Produces flat welds with minimal post-processing.

- Easy Operation: No certification required; quick learning curve for new operators.

Key Features

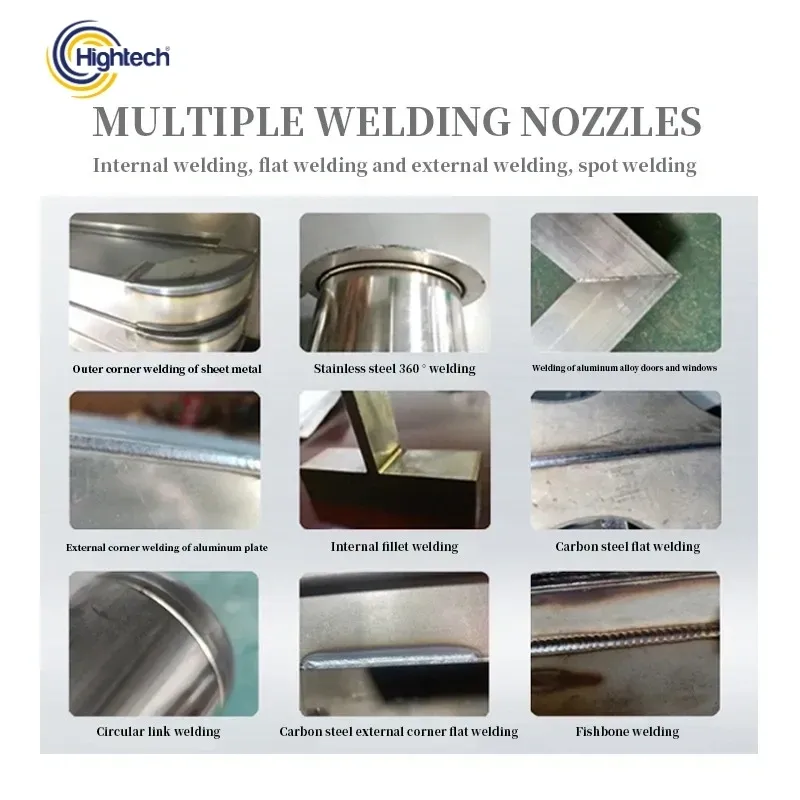

Versatile Welding Head: The lightweight handheld welding gun supports full-angle welding, making it suitable for complex joints, curved surfaces, and precision metalwork.Copper Nozzles Set: Includes five interchangeable copper nozzles (fat angle, inner corner, outer corner, wire-feeding, and cutting) to meet a wide variety of welding tasks.Raycus Laser Source: Equipped with a reliable Raycus laser module offering high conversion efficiency, long service life, and stable 24-hour operation.Advanced Cooling System: The integrated chiller prevents overheating, dust accumulation, and condensation, ensuring consistent performance in industrial environments.Extended Welding Range: A durable 5–10m optical fiber cable allows flexible, long-distance operation without sacrificing precision or stability.Why Choose HT FW-1500

User-Friendly Operation: Designed for simplicity—operators can begin welding after just 30 minutes of training, eliminating the need for professional certification.Superior Weld Appearance: Produces flat, uniform welds with minimal deformation, significantly reducing finishing time.High Productivity & Energy Savings: Fast welding speeds and low power consumption improve output while keeping operational costs low.Durable & Low-Maintenance Design: Reinforced metal structure, premium components, and minimal consumable usage ensure long-term reliability and reduced service costs.Applications

Metal Fabrication & Workshops: Ideal for welding stainless steel, carbon steel, aluminum, and copper components.Industrial Manufacturing: Suitable for rapid, precise welding in assembly lines, mechanical structures, and equipment production.Custom Projects & Fine Welding: Supports intricate welding tasks for frames, artistic metalwork, tools, and prototypes.Repair & Restoration: Effective for repairing cracks, filling gaps, and restoring worn metal components with professional-quality results.Get Quote

Please share your company name, email address, and the product you are looking for