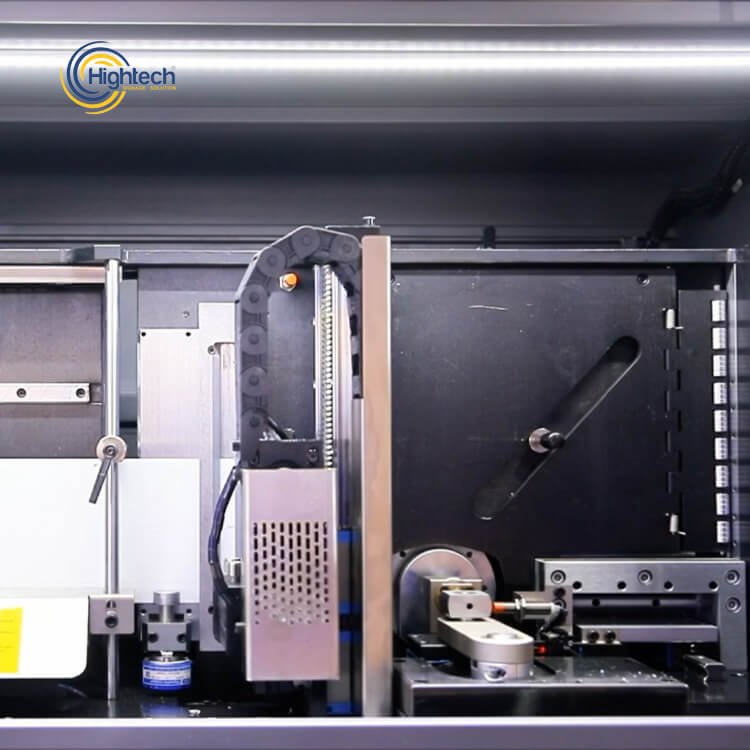

HTZ5 Channel Letter Bending Machine

Category: Channel Letter Bending Machines

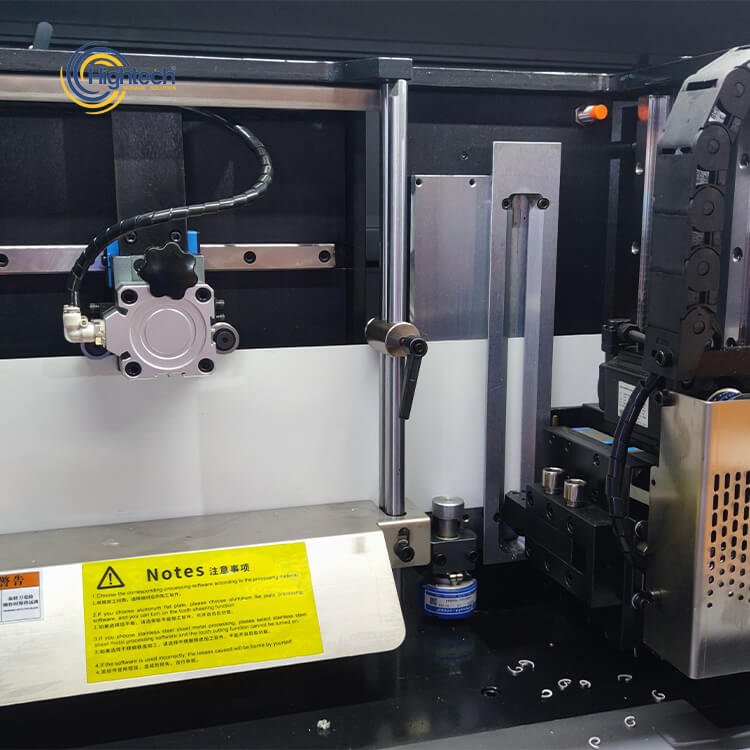

Servo system: Custom servo parameters

Photoelectric inductive:

Panasonic Omron photoelectric induction switch, Panasonic photoelectric induction switch

Motion control: ADTECH motion control

systemMechanicai drive: High precision ball screw and linear guide rail

Product Gallery

Technical Parameters

| Warranty |

1year |

|---|---|

| Slotting System |

Servo planer slotting system |

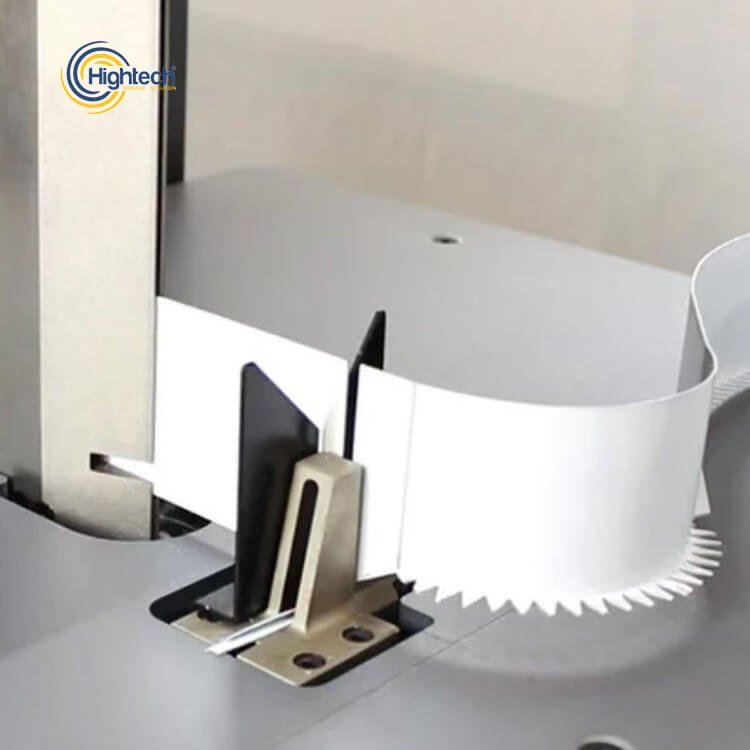

| Bending System |

Servo double blade alterating bending |

| Feeding Method |

Robotic Feeding |

| Material Thickness |

Scissor teeth folding: 0.3-1.2mm |

| Applicable Material |

Aluminum plate ,Galvanized sheet ,Stainless Steel |

| Minimum bending angle |

R6mm |

| Notch cutting angle |

30°/120° |

| Power |

AC220V±10% ,50HZ |

| Gas source |

0.6m3/min |

| Weight |

700KG |

| Overall dimension |

3000*1300*1620mm |

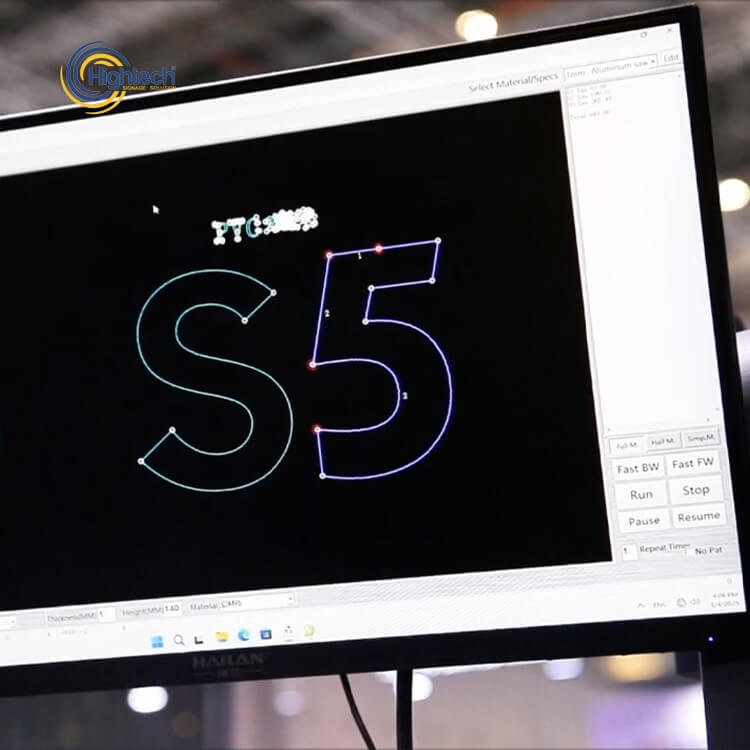

| Input File Format |

AI ,DXF ,PLT |

Introducing HTZ5 Channel Letter Bending Machine

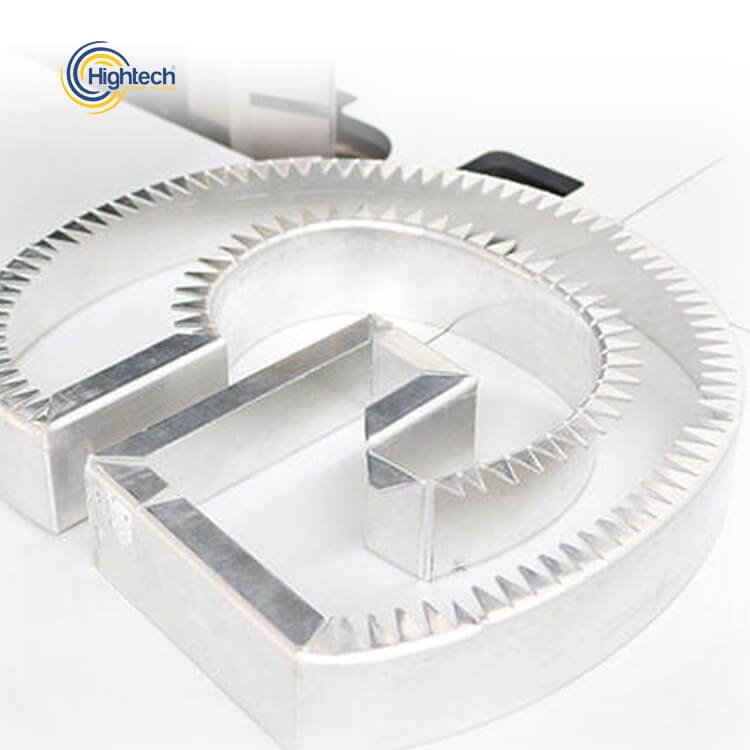

The HTZ5 combines high-precision, high-speed, and high-stability in a fully automated bending solution for professional signage production. It’s designed to meet the demanding needs of modern sign makers with its advanced features and robust build. Ideal for handling wide and thick materials with unmatched accuracy.- Double Blade Alternating System – Offers precision bending for complex channel letter shapes.

- Planer Knife Slotting – Creates perfect slots without causing surface marks on materials.

- Advanced Feeding Mechanism – Custom servo motors and grinding-grade ball screws ensure smooth, fast material feeding.

- High-Speed Bending – Custom servo-driven bending shaft for fast, accurate operations on various material types.

Key Features

Double Blade System – Alternating blades deliver precise bends without material distortion. Slotting Precision – Planer knife system ensures consistent slotting for intricate designs. Smooth Feeding – Advanced servo and ball screw system enables fast, precise material movement. Stable Bending – High-precision reducer and customized servo ensure stable, fast bending operations.Why Choose HTZ5

Superior Speed – High-speed bending and feeding for quick production cycles. Precision Control – Maintains ±0.1 mm accuracy across all bending and slotting tasks. Durable Build – Integral cast structure prevents pinch marks, enhancing material handling. Versatile Materials – Efficient with both wide and thick materials, perfect for complex signage.Applications

Signage Fabrication – Ideal for illuminated and non-illuminated channel letter production. Material Handling – Works with wide, thick materials for precision channel bending. Custom Designs – Supports precise cuts and bends for detailed and varied signage projects.Get Quote

Please share your company name, email address, and the product you are looking for