Blog

Laser Cutting | A Guide to Precision Technology

Table of Contents

What is Laser Cutting? A Guide to Precision Technology

Laser cutting has become one of the most important precision technologies in modern manufacturing and signage. By using a highly focused laser beam, this method allows clean, accurate, and efficient cutting across a wide range of materials. For industries such as signage and channel letter fabrication, laser cutting provides unmatched speed and quality compared to traditional tools.

Understanding how this technology works, the machines available, and the benefits for specific applications can help businesses make the right investment.

How Does Laser Cutting Work?

To understand what is laser cutting, imagine a focused beam of light powerful enough to melt or vaporize materials along a chosen path. This process is carried out by a laser cutting machine, which directs the beam through mirrors and lenses to achieve maximum precision. Because there is no direct physical contact, the cut edges remain smooth and consistent.

In practice, laser cutting involves three main steps: generating the laser beam, focusing it onto the surface, and guiding it according to the programmed design. This technology is widely used in channel letter laser cutting, where clean, accurate lines are essential for producing professional signage.

Benefits of Laser Cutting for Channel Letter Fabrication

Laser cutting provides significant advantages for producing channel letters with high precision and efficiency. This technology allows sign makers to achieve clean edges, consistent shapes, and faster production times compared to traditional cutting methods. By using laser cutting machines, shops can reduce errors, minimize material waste, and create professional-quality signage that meets modern industry standards.

Key benefits include:

- High Precision and Accuracy – Laser cutting produces smooth, detailed edges that require little to no finishing, ensuring each letter matches the design perfectly.

- Speed and Efficiency – Cuts complex shapes quickly, allowing higher production volumes without compromising quality.

- Material Flexibility – Works with metals like aluminum and stainless steel, as well as acrylic and other non-metallic materials for illuminated letters.

- Consistent Production – Every cut is identical to the programmed design, ensuring uniformity across multiple letters.

- Reduced Waste and Costs – Optimized cutting paths minimize material loss, making projects more cost-effective.

Materials Compatible with Laser Cutting for Channel Letters

One of the main strengths of laser cutting is its ability to handle a wide range of materials used in signage. Metals such as aluminum and stainless steel are among the most common choices because they offer durability and a professional finish. Aluminum is lightweight and easy to cut, while stainless steel provides strength and corrosion resistance for long-lasting signs.

In addition to metals, non-metallic materials like acrylic are frequently used for illuminated letters, as they allow light to pass through and create vibrant effects. This versatility makes laser cutting the go-to method for modern channel letter fabrication, giving sign makers the flexibility to bring creative designs to life.

the global leader in channel letter bending machines and equipment

Hightech Industry Group

Applications of Laser Cutting in Signage and Advertising

Laser cutting has become a crucial tool in modern signage and advertising, allowing businesses to produce high-quality, visually appealing signs with precision and efficiency. Its ability to handle intricate designs and various materials makes it ideal for creative and professional applications.

Key applications include:

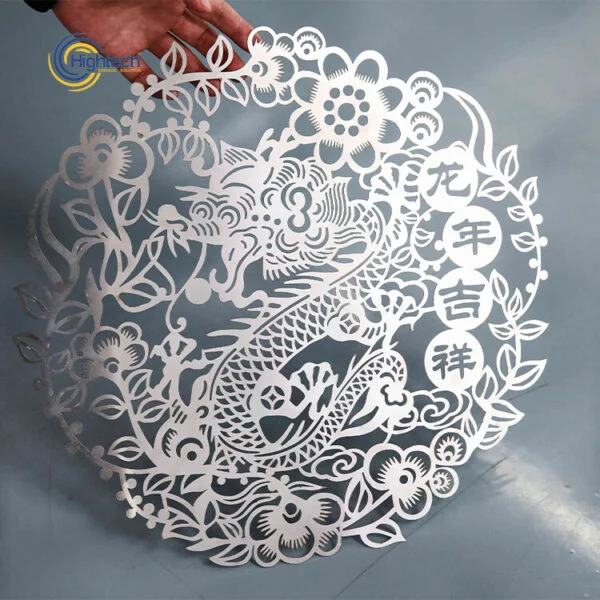

- Channel Letter Fabrication – Creates precise metal and acrylic letters for storefronts, office buildings, and illuminated signs, ensuring clean edges and consistent shapes.

- Custom Logos and Shapes – Produces detailed and complex designs that are difficult to achieve with traditional cutting methods, enhancing branding and visual appeal.

- Illuminated Signage – Works with acrylic and LED-compatible materials to craft bright, professional lighting effects that attract attention.

- Advertising Displays – Cuts exhibition stands, point-of-sale displays, and promotional boards accurately and efficiently.

- Prototyping and Small-Batch Production – Ideal for rapid prototyping and custom orders, reducing setup time while maintaining high precision.

This versatility makes laser cutting an essential part of modern channel letter laser cutting and broader signage production.

Types of Laser Cutting Machines for Channel Letter Bending

Laser cutting machines vary depending on the material and precision required for channel letter fabrication.

Two of the most commonly used types are Fiber Laser Cutting Machines and CO₂ Laser Cutting Machines, each suited to different applications. Understanding their features helps sign makers choose the right tool for their workflow.

Fiber Laser Cutting Machines

Fiber laser cutting machines use a solid-state laser source combined with optical fibers to produce a high-intensity beam. They operate at a wavelength of approximately 1.06 microns, making them highly effective for cutting metals such as stainless steel, aluminum, carbon steel, brass, and copper.

Fiber lasers offer high cutting speed, excellent edge quality, low maintenance, and energy efficiency. However, they are less effective on non-metallic materials like acrylic, wood, or glass due to low absorption. These machines are ideal for precision metal channel letter laser cutting.

CO₂ Laser Cutting Machines

CO₂ laser cutting machines use a gas-based laser source, typically CO₂, with a wavelength of around 10.6 microns. They perform exceptionally well on non-metallic materials such as acrylic, wood, leather, glass, and plastics, producing smooth cuts and high surface quality.

CO₂ lasers have lower energy efficiency and require more maintenance compared to fiber lasers, including regular checks of mirrors and the laser tube. They are limited when cutting reflective metals like copper or brass unless high power or coatings are used. CO₂ machines are perfect for illuminated or decorative channel letter fabrication using acrylic or other non-metal materials.

Key Factors for Choosing the Right Laser Cutting Machine

Selecting the appropriate laser cutting machine for channel letter production is critical for efficiency, precision, and material compatibility. Considering the right factors ensures that your investment meets production demands and delivers consistent, high-quality results.

Material Compatibility

The first consideration is whether the machine can handle the materials you use most often. Fiber lasers excel at cutting metals like aluminum, stainless steel, and brass, while CO₂ lasers are better suited for non-metallic materials such as acrylic, wood, and glass. Ensuring material compatibility prevents damage and improves cutting quality.

Bending Accuracy and Precision

Precision is vital in channel letter fabrication, where even minor deviations can affect assembly and visual appeal. Machines with fine control over the laser path deliver consistent results and reduce post-processing work.

Speed and Efficiency

High production volumes require machines that cut quickly without compromising quality. Automatic or CNC-controlled lasers improve efficiency, reduce manual labor, and shorten turnaround times for large orders.

Durability and Build Quality

A robust machine ensures reliable performance over time. Components should withstand continuous use, particularly for metal cutting, where energy intensity and heat can impact machine longevity.

After-Sales Support and Service

Reliable technical support, maintenance options, and availability of replacement parts are essential. A machine with strong service backing ensures minimal downtime and long-term operational success.

Conclusion

Laser cutting has revolutionized channel letter fabrication, offering unmatched precision, speed, and flexibility across a variety of materials. Understanding what is laser cutting, the types of machines available—fiber and CO₂ lasers—and the key factors in selecting the right equipment helps sign makers optimize production.

By choosing the appropriate machine for metals or acrylic, shops can create high-quality, professional channel letters efficiently, reduce material waste, and meet modern signage demands.