4 in 1 Fiber Laser Welding machine HT FW 3000

Categories: 4 in 1 Fiber Laser Welding Machine, Laser Welding Machines

Product Gallery

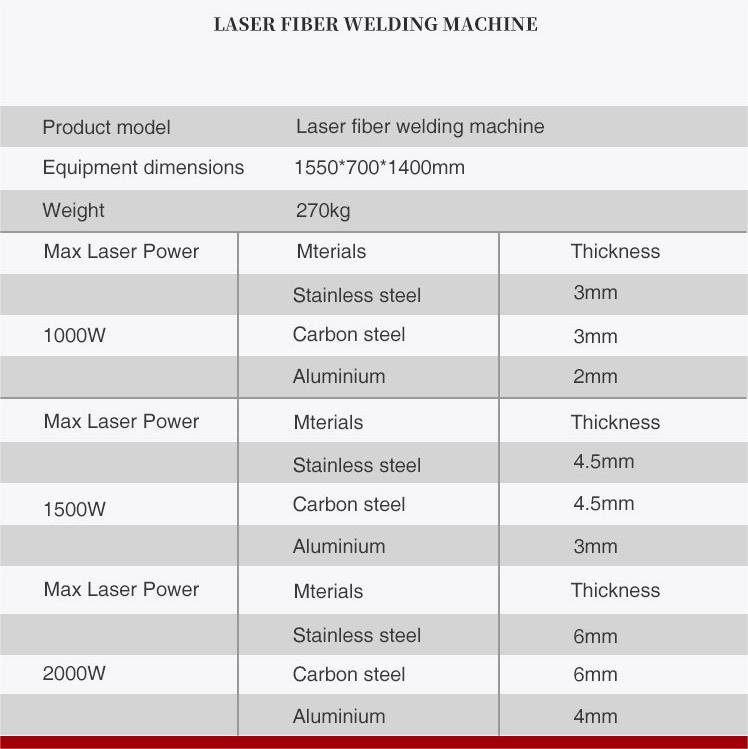

Technical Parameters

| Warranty |

1year |

|---|---|

| Optical Fiber Laser |

Maxphotonics Industrial Edition |

| Chiller |

Huaku ,S&A Chiller |

| Control system |

built-in craft package easy to get started ,Supporting system |

| Machine Cabinet |

Hightech, industrial-grade anti-jamming cabinet |

| Weight |

215Kg |

| Wire Feeder |

Double-drive wire feeder ,preciseand adjustable speed ,smooth wire feeding |

| Power |

Single Phase ,AC220V±10% ,50HZ ,60Hz |

| Welding thickness |

3000W:Stainless steel:8mm;Carbon steel:8mm |

| Put the environment |

Flat, with no vibration or impact |

| Working environment |

10~40℃ ,humidity: ≤70% |

| Cooling Method |

Hydrocooling |

| Laser wave length |

1064nm (±10nm) |

| Applicable power (W) |

≤3000W |

| Collimator Specification (mm) |

D16-F60 |

| Focus mirror size (mm) |

120- F150 |

| Focus vertical adjustment range (mm) |

±10mm |

| Scan width-Welding |

F150-0~30mm ,F400-0~60mm ,F800-0~120mm |

| Protective mirror size (mm) |

D18xT2 |

| Gun body air pressure (Bar) |

≤15Bar |

Introducing 4 in 1 Fiber Laser Welding machine HT FW 3000

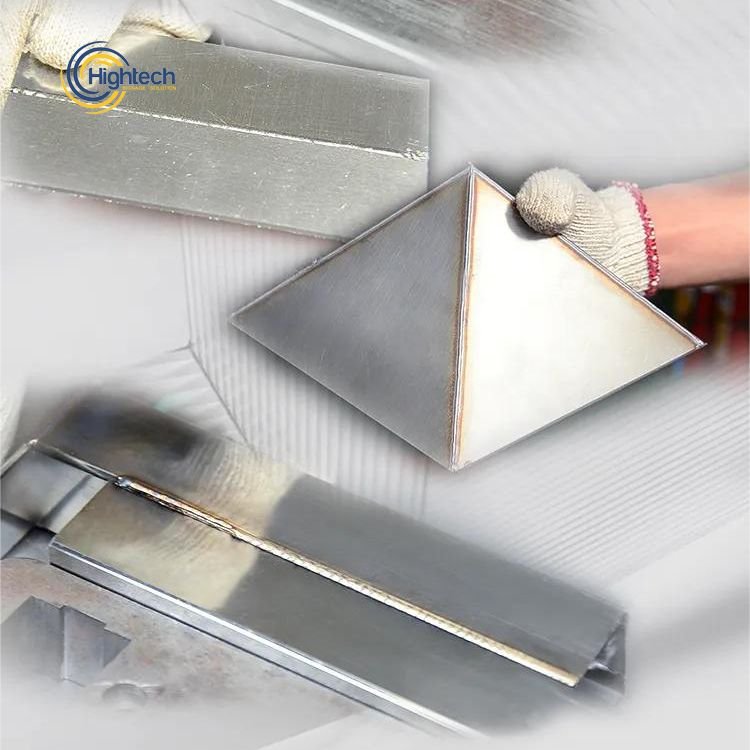

The HT FW-3000 4-in-1 Fiber Laser Welding Machine is a high-power, industrial-grade welding system designed for maximum speed, precision, and stability. With a powerful 3000W configuration and support for overlap, spot, butt, tower, edge, and T-welds, it delivers smooth, clean seams with no secondary grinding required. Its reinforced structure, advanced cooling, and upgraded laser source make it ideal for heavy-duty production environments.Key Highlights

- High-Power Performance: 3000W output enables deeper penetration and faster welding on thick metals.

- Multi-Angle Weld Capability: Suitable for all weld types—including spot, butt, overlap, and T-welds.

- Industrial Efficiency: Operates 2–10× faster than traditional welding machines.

- Clean & Stable Results: Flat, uniform welds with minimal finishing and reduced thermal deformation.

Key Features

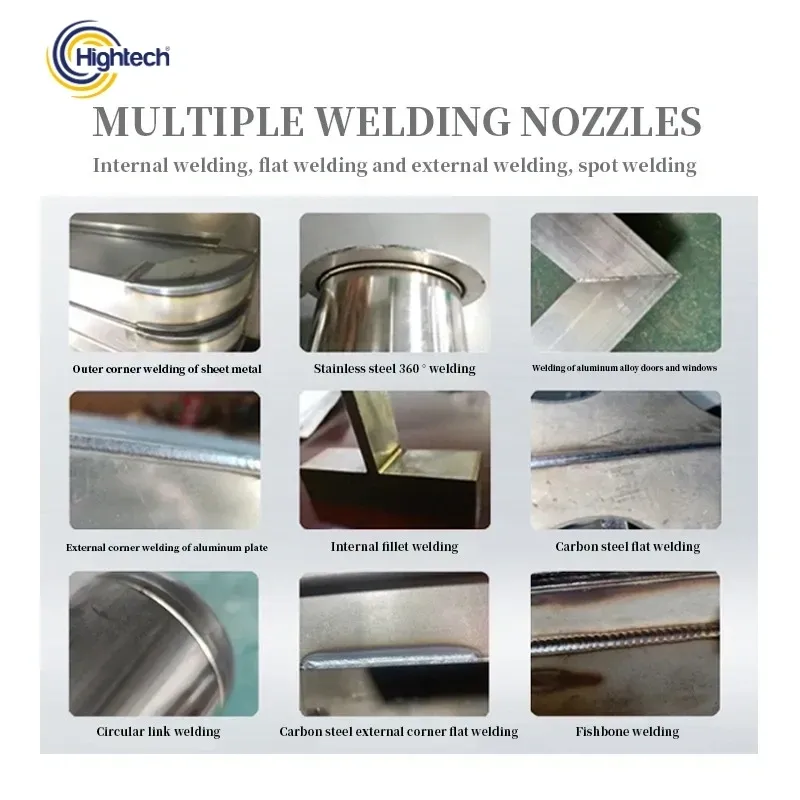

Advanced Swing Welding Head: The ergonomic, lightweight hand-held welding gun supports full-angle operation, enabling precise welding even on complex components and curved surfaces.Efficient Copper Nozzle System: A complete set of welding nozzles supports inner/outer corner welding, wire-feeding, cutting, and high-speed bead formation, ensuring versatility across applications.Raycus High-Power Laser Source: Equipped with a next-generation Raycus laser generator offering high electro-optical conversion, stable 24/7 operation, and superior welding penetration.Integrated Cooling System: The built-in chiller provides consistent temperature control, prevents condensation and dust contamination, and ensures long-term stability—ideal for industrial workloads.Extended Fiber Cable: A durable 5–10m optical fiber cable allows wide-range welding without restricting operator movement, perfect for large workpieces or production lines.Why Choose HT FW-3000

Effortless Operation: Requires no welding certificate; new operators can begin working after a short training period.Superior Weld Quality: Produces consistent, flat welds with minimal spatter, reducing grinding and post-processing time.High Productivity: Extreme welding speed significantly increases output, especially in thick-metal fabrication.Low Maintenance: Long-life laser module, robust cabinet design, and minimal consumable usage ensure reduced downtime and long-term reliability.Applications

Metal Fabrication & Workshops: Efficient welding of stainless steel, carbon steel, aluminum, and mixed-metal components.Automotive & Machinery Production: Reliable for body parts, brackets, structural frames, and mechanical assemblies.Home Appliance & Kitchenware Manufacturing: Supports clean, precise welding of sinks, cabinets, panels, and thin-sheet components.Advertising & Custom Metalwork: Ideal for welding metal letters, decorative structures, frames, and artistic designs.Get Quote

Please share your company name, email address, and the product you are looking for