Mini Fiber Laser Jewellery Welding Machine HT JW MD 200

- Ultra-Compact Design – Features industry-leading integrated circuits and optical systems in a space-saving package with imported high-performance components, delivering powerful performance in a small footprint while maintaining easy maintenance and diagnostic capabilities.

- Precision Welding – Offers fast, high-accuracy welding that prevents surface damage and deformation, ensuring perfect jewelry restoration with excellent finish quality.

- Advanced Observation – Equipped with dual viewing system combining 10X HD microscope and built-in CCD camera for clear, real-time monitoring of welding process.

- Safety Features – Includes automatic eye-protection shutter synchronized with laser operation and gas shielding system to ensure clean, oxidation-free welds.

- Reliable Performance – Uses top-quality Dongjun crystal and imported ceramic cavity for stable, high-efficiency operation with long-lasting imported xenon lamp.

- User-Friendly – Multilingual interface supporting 8 languages for worldwide operation convenience.

- This compact welding solution combines space efficiency with professional-grade performance, offering jewelers precise, safe and easy-to-use welding capabilities.

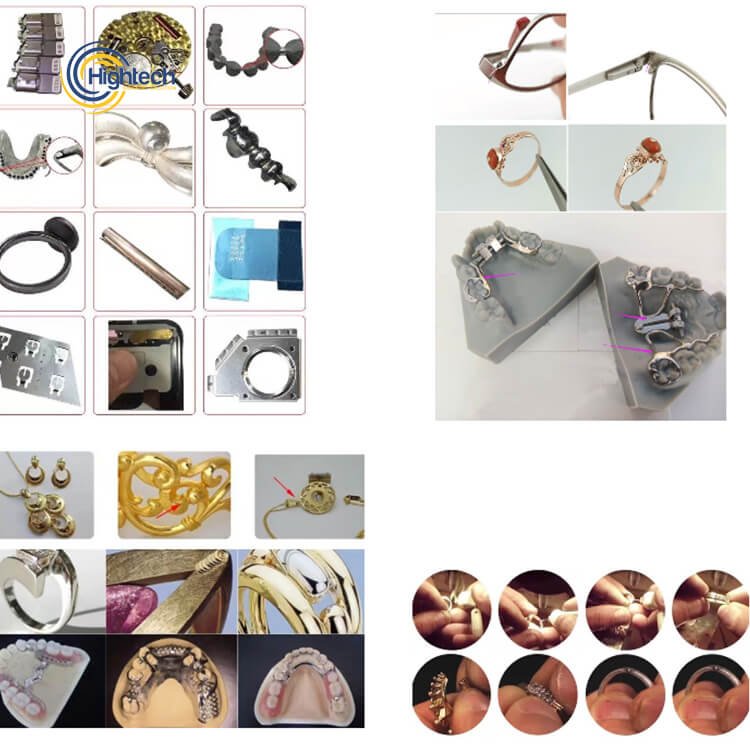

Product Gallery

Technical Parameters

| Laser Power |

200W |

|---|---|

| Laser type |

YAG |

| Laser wave length |

1064nm |

| Maximum energy per pulse |

60J |

| Pulse width |

0.1-10ms |

| Laser spot size adjusting range |

0.1-3mm |

| Laser welding frequency |

1-15Hz |

| Focal length |

110mm |

| Aiming and positioning |

10X microscope and cross cursor CCD dual display positioning |

| Cooling Method |

Built-in food grade stainless steel air cooling water tank 4L |

| Power |

<6Kw ,AC220V±10% ,50HZ ,60Hz |

| Size |

570*340*430mm (microscope installed) |

| Weight |

38kg |

| Packaging size and weight |

48Kg ,625*395*630mm |

Introducing Mini Fiber Laser Jewellery Welding Machine HT JW MD 200

The HT JW-MD 200 is an ultra-compact, precision fiber laser welding system engineered specifically for jewellery repair, manufacturing, and micro-welding applications. Its advanced optical components, high-accuracy pulse control, and integrated viewing systems deliver clean, deformation-free welds ideal for gold, silver, platinum, and delicate alloy work. Combining portability with professional-grade capability, it offers reliable performance for workshops of any size.Key Highlights

- Ultra-Compact Build: High-performance circuits and optics integrated into a space-saving design.

- Precision Micro-Welding: Fast, accurate welding with minimal heat impact and zero surface deformation.

- Dual Viewing System: 10X microscope + CCD camera for clear, real-time monitoring.

- Safe & Clean Operation: Auto eye-protection shutter with gas shielding for oxidation-free welds.

Key Features

High-Accuracy Welding Performance: Delivers stable, finely controlled laser output suitable for repairing chains, prongs, rings, micro-joints, and delicate components without discoloration or distortion.Dual Observation System: Combines a 10X HD microscope with a built-in CCD camera, allowing jewelers to monitor the weld area with exceptional clarity during and after laser discharge.Robust Optical Components: Equipped with a Dongjun crystal and imported ceramic cavity alongside a high-quality xenon lamp for consistent, long-lasting laser performance.User-Friendly Interface: Features a multilingual operating panel supporting 8 international languages, making operation simple for global workshops and training environments.Why Choose HT JW-MD 200

Exceptional Precision for Fine Jewellery: Engineered for micro-scale welding tasks where accuracy, finish quality, and minimal heat spread are essential.Compact & Workshop-Friendly: Small footprint fits easily into jewelry stores, repair studios, and small production environments without sacrificing power.Stable & Low-Maintenance Operation: Durable internal components and efficient cooling reduce service needs and ensure long-term reliability.Professional-Grade Results: Provides smooth, clean welds that require little to no finishing—ideal for luxury jewellery restoration.Applications

Jewellery Repair & Restoration: Welding of chains, settings, prongs, bezels, and fine components with minimal heat impact.Custom Jewellery Manufacturing: Precision joining for gold, silver, platinum, and alloy components in bespoke designs.Micro-Welding Workshops: Suitable for delicate assembly of small metal parts requiring ultra-clean, accurate welds.Watch & Accessory Repair: Ideal for micro-welding tasks in watch cases, bands, hinges, and fine metal accessories.View Catalogue

Get Quote

Please share your company name, email address, and the product you are looking for