Cabinet Fiber Laser Jewellery Welding Machine HT JW CB 200

- Industry Pioneer – The original jewelry welding machine that set the design standard for subsequent models. Features powerful standard power supply and compressor-cooled water system for continuous operation, especially effective for high-purity precious metals.

- High-Speed Precision – Delivers fast, accurate welding while conserving energy. Eliminates surface damage and deformation common in traditional methods, preserving jewelry quality and appearance.

- Enhanced Visibility – Comes standard with 10X micro lens, with option to upgrade to microscope+CCD dual observation system.

- Eye Protection System – Automatic synchronized shutter blocks light during welding to prevent eye strain.

- Dual Control Options – Features both control panel and convenient joystick operation for parameter adjustments.

- Oxidation Protection – Integrated gas valve provides protective atmosphere during welding.

- Efficient Fume Extraction – Built-in ventilation quickly removes smoke for clearer visibility and environmental protection.

- Premium Components – Uses top-quality Dongjun crystal for stable power, imported ceramic cavity for high efficiency, and long-lasting domestic xenon lamps for cost-effective operation.

- Key Advantages: Combines proven reliability, superior performance, and user-friendly features for professional jewelry welding applications.

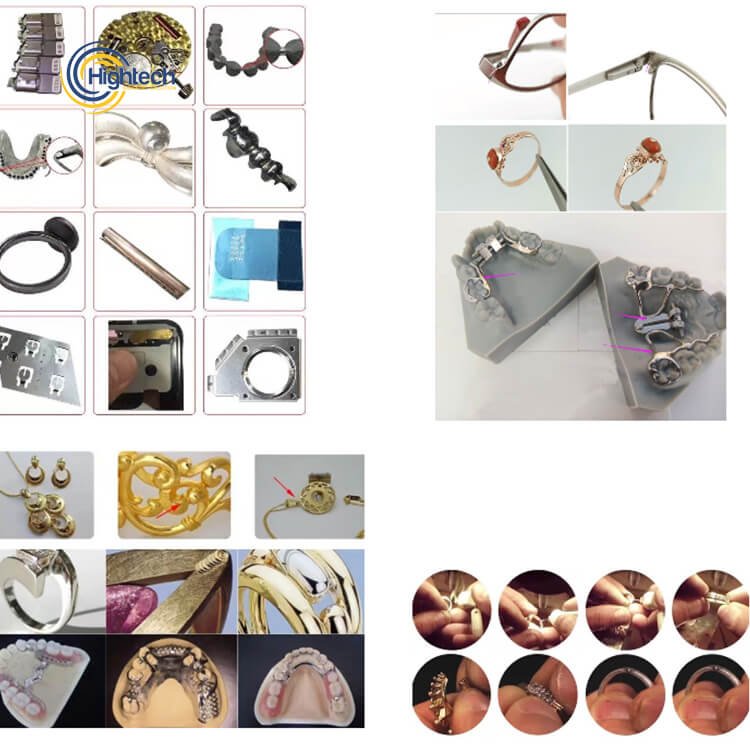

Product Gallery

Technical Parameters

| Laser Power |

200W |

|---|---|

| Laser type |

YAG |

| Laser wave length |

1064nm |

| Maximum energy per pulse |

85J |

| Pulse width |

0.1-3ms |

| Laser spot size adjusting range |

0.3-3mm |

| Focal length |

110mm |

| Laser welding frequency |

1-30Hz |

| Aiming and positioning |

10X microscope |

| Cooling Method |

Water-cooled compressor refrigeration |

| Power |

Peak 7.5kw ,AC220V±10% ,50HZ ,60Hz |

| Weight |

126Kg |

| Size |

1040*580*1280mm |

| Packaging size and weight |

1080*655*1350mm ,165kg |

Introducing Cabinet Fiber Laser Jewellery Welding Machine HT JW CB 200

The HT JW-CB 200 is a professional cabinet-style fiber laser welding system designed for precise jewelry applications. Built with robust cooling, premium optical components, and advanced control options, it delivers fast, high-accuracy welds while preserving the surface quality of precious metals. Its ergonomic design, dual observation system, and integrated safety features make it ideal for continuous, reliable operation in professional workshops.Key Highlights

- Compact Cabinet Design: Efficient space use with compressor-cooled water system for continuous performance.

- Precision Welding: Fast, accurate welds without deformation or surface damage.

- Enhanced Observation: Standard 10X micro lens with optional microscope+CCD dual monitoring.

- Safe & Clean Operation: Automatic eye-protection shutter, gas shielding, and built-in fume extraction.

Key Features

High-Speed Precision Welding: Ensures smooth, accurate welding on gold, silver, platinum, and other high-purity metals with minimal heat impact.Advanced Observation System: Dual viewing capability allows precise monitoring of detailed welds for flawless results.Safety & Oxidation Protection: Automatic shutter and integrated gas valve provide eye protection and prevent oxidation during welding.Flexible Control Options: Intuitive joystick and panel interface enable easy adjustment of welding parameters.Premium Components: Dongjun crystal, imported ceramic cavity, and long-life xenon lamps guarantee stable, energy-efficient performance.Why Choose HT JW-CB 200

Professional Reliability: Built for continuous operation with consistent high-quality welds.Workshop Efficiency: Cabinet-style design supports larger workpieces while saving space.Flawless Weld Quality: Minimal finishing required, preserving jewelry aesthetics.User-Friendly: Ergonomic controls and observation system reduce fatigue and increase productivity.Applications

Jewelry Fabrication: Welding rings, chains, and intricate components with high precision.Repair & Restoration: Restoring prongs, bezels, and delicate jewelry parts.Custom Jewelry Production: Supports bespoke designs and complex assemblies requiring precise micro-welding.Professional Workshops: Ideal for continuous use in small to medium-sized jewelry and accessory production studios.View Catalogue

Get Quote

Please share your company name, email address, and the product you are looking for