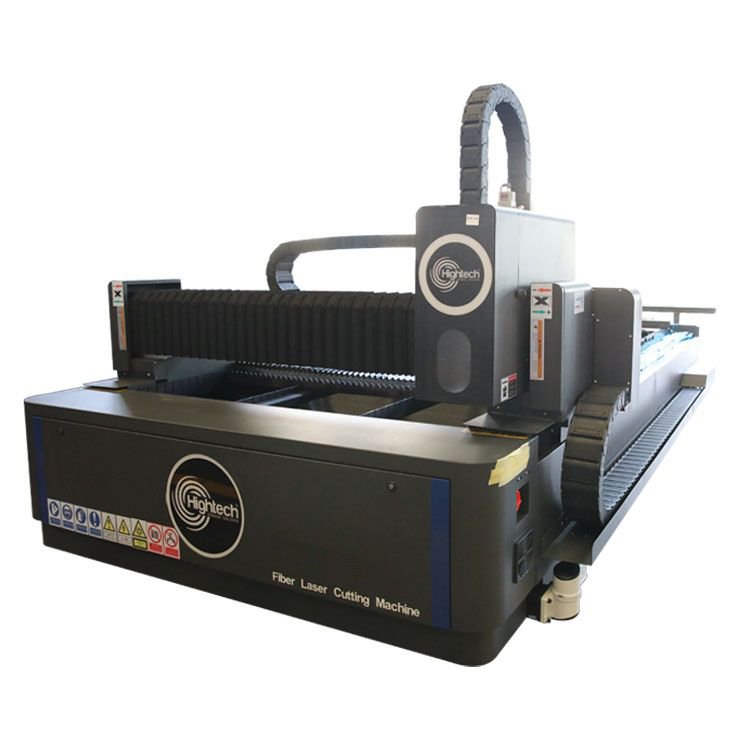

HT FC-2040 Fiber Laser Cutting Machine

Categories: Fiber laser Cutting Machine, Machinery

- High-quality fiber laser source and head for exceptional beam quality and power stability, with maintenance-free operation

- Runs on air, oxygen, or nitrogen, providing flexible cutting options for different materials

- Industrial-strength construction with three-axis dust-proof design, XY-axis rack drive, and Z-axis screw drive

- Precision servo system with high-stability electronic components for accurate and reliable performance

- Auto-focus laser head with capacitive height control for automatic adjustment to plate variations

Product Gallery

Technical Parameters

| Warranty |

1year |

|---|---|

| Weight |

1200Kg |

| Power |

Single Phase ,AC220V±10% ,50HZ |

| Outlinesize |

3900.5*2760*1650mm |

| X-axis Travel |

1500mm |

| Z-axis Travel |

80mm |

| Work Area |

1300*1500mm |

| Protection Level of Total Powersupply |

IP54 |

| Maximum acceleration |

0.4G |

| Repeated positioning |

±0.02mm |

| Applicable Material |

Aluminum alloy ,Brass ,Carbon Steel ,Copper ,Electrolytic Sheet ,Galvanized sheet ,Manganese Alloy ,Silicon Steel ,Stainless Steel ,Titanium Alloy |

| Table maximum load |

700Kg |

| Positioning Accuracy |

±0.05mm |

| Cutting Speed |

60m/min |

Introducing HT FC-2040 Fiber Laser Cutting Machine

The HT FC-2040 Fiber Laser Cutting Machine is a high-precision, industrial-grade system designed for efficient cutting of a wide range of metal sheets. Featuring automatic focusing technology, intelligent tracking, and free nesting systems, it delivers stable, accurate, and reliable performance for high-volume manufacturing applications. Built with robust construction and advanced control, the FC-2040 ensures consistent results across carbon steel, stainless steel, aluminum, and other alloys.Key Highlights

- Automatic Focusing & Tracking: Ensures precise cutting on varied plate thicknesses.

- Wide Material Compatibility: Cuts carbon steel, stainless steel, aluminum, brass, copper, titanium, and more.

- Industrial-Grade Construction: High-strength welded bed and aviation-grade aluminum beam for stability and shock absorption.

- Advanced Control System: FSCUT system with intelligent power monitoring and precise motion control.

Key Features

- Precision Transmission: YYC guide rails and helical rack drive provide smooth, accurate movement with reduced driving torque.

- Durable Machine Bed: 600°C annealed high-strength bed ensures rigidity and long-term stability during high-speed operation.

- High-Quality Laser Components: Raycus laser source and Raytools cutting head deliver stable power, fast cutting, and low maintenance.

- Optimized Cooling: Hanli water chiller system maintains laser performance, protects components, and enables continuous operation.

Why Choose HT FC-2040

- High Cutting Accuracy: Automatic focusing and advanced motion control provide clean, precise edges on complex designs.

- Reliable Industrial Performance: Robust frame and reinforced aluminum beams reduce vibration and maintain alignment under heavy workloads.

- Efficient Workflow: Free nesting system and intelligent tracking increase productivity and reduce material waste.

- User-Friendly Operation: FSCUT control system allows easy parameter adjustments, monitoring, and smooth, safe operation.

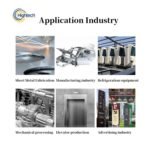

Applications

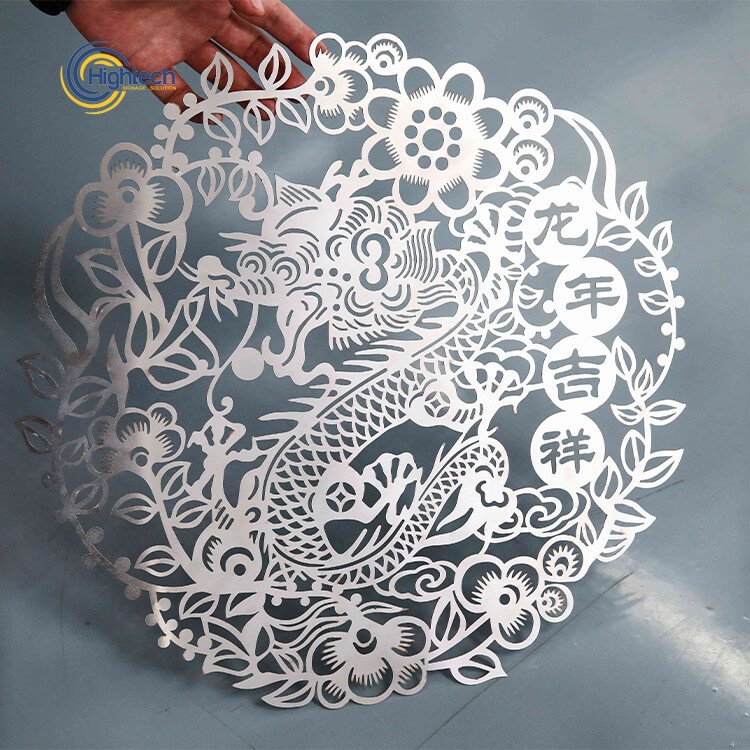

- Sheet Metal Fabrication: Ideal for carbon steel, stainless steel, aluminum, galvanized sheets, and titanium alloy components.

- Manufacturing Industry: Suitable for machinery, refrigeration equipment, and precision metal parts.

- Construction & Elevator Industry: Used for metal panels, structural components, and elevator fabrication.

- Advertising & Signage: Accurate cutting for metal letters, decorative panels, and custom signage.

Get Quote

Please share your company name, email address, and the product you are looking for